Build Big (Boat) Parts

researchother machineextrusionhack

More Information

INTRO

Created 4yCreated over 4 years agoUpdated 4yUpdated over 4 years ago

Okay, so to get an idea what we've done so far, you can have a look at this How-to, where we documented the process of building the world's first recycled plastic sailing dhow - a prototype for the big boat we want to build now:

https://community.preciousplastic.com/how-to/build-a-flipflopi-boat

We already sailed on two expeditions (Lamu-Zanzibar 2019 and around Lake Victoria 2021) to spread awareness around plastic pollution, highlight local activities to teach and inspire more people with creative solutions, and push for individual as well as political actions towards a cleaner and more circular East Africa.

The boat is not only an impressive thing to showcase the potential of plastic, but really brought together a lot of people from different levels, creating stronger communities and activities to build a better system around plastic (and all resources we use).

AND NOW WE ARE FINALLY STARTING THE PROCESS OF BUILDING THE BIG FLIPFLOPI.

A 24m sailing dhow for bigger expeditions with bigger impact!

But there are still a lot of things we have to figure out and improve, so here we go :)

Core Challenge

Created 4yCreated over 4 years ago

There are many challenges that we're likely to face throughout this process but there are a couple that are worth pointing out here as they make up what we think is the 'core' challenge of this task.

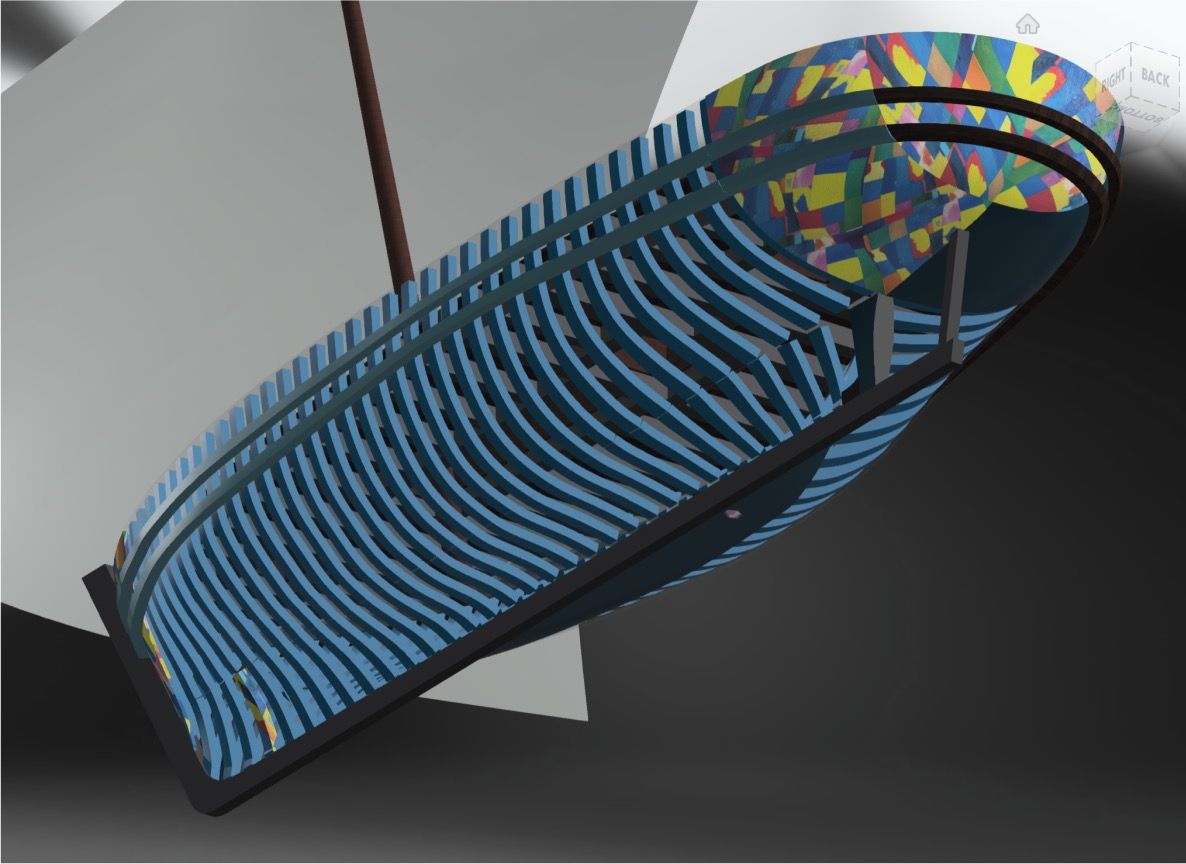

1) Making many large unique parts (CAD concept shown in first image)

2) Ensuring these parts are of a consistently high quality

In conventional plastic production, a mould can be justified after a certain number of parts (as moulds are a costly item). Here, we are only making one boat so a mould for each part would be a costly and wasteful process.

The concepts that follow aim to propose a process to produce large quality parts consistently without the need for an individual mould for each part.

Concept 1 - Existing Moulds

Created 4yCreated over 4 years agoUpdated 4yUpdated over 4 years ago

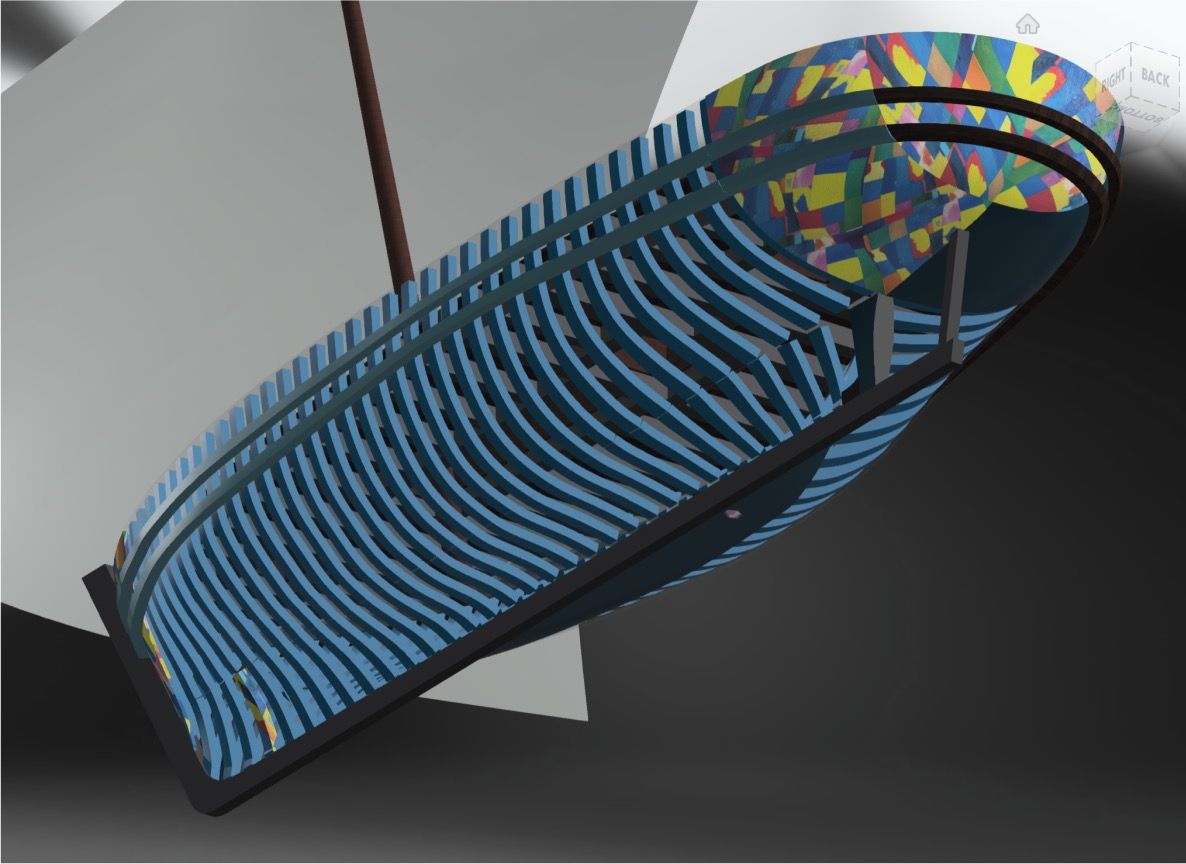

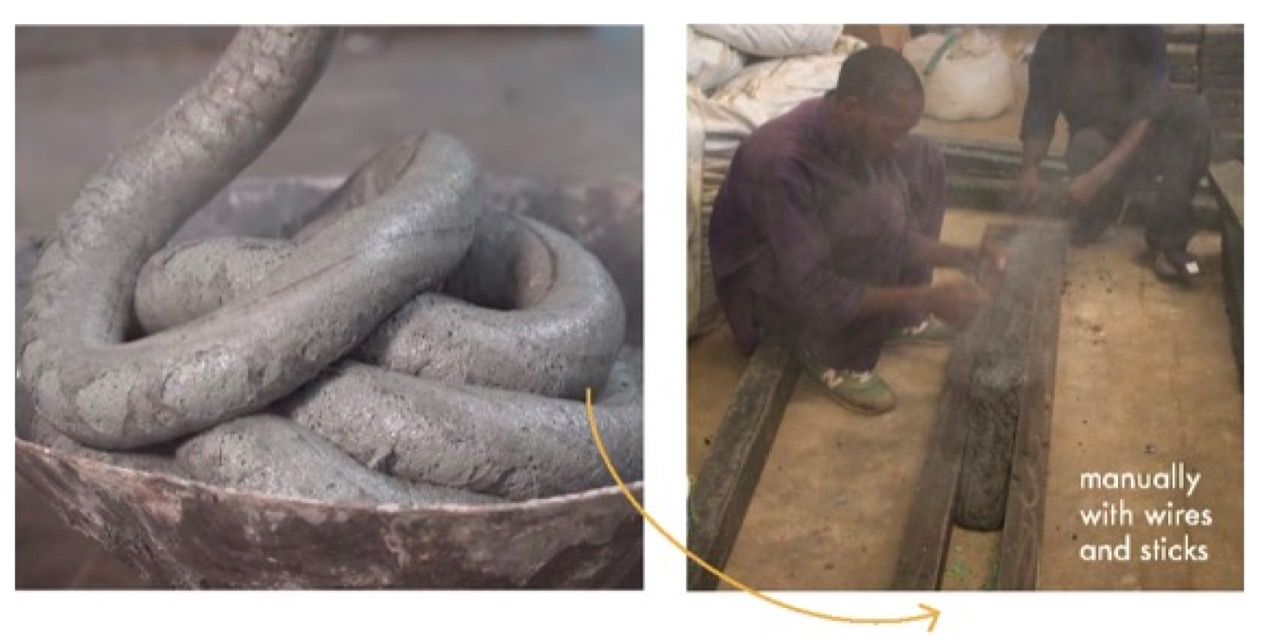

When building our prototype, these open 'cake tin' moulds were used. Because of the many unique parts, they were continuously made, cut and reshaped into the next mould. This was a lot of work and also resulted in a lower quality material because of the inability to build up any pressure to squeeze out air pockets.

If we use this process again, we're going to need more heat and pressure.

👍 PROS:

- moulds already exist

- low tech process

👎 CONS:

- can't make high quality parts

- very manual process which could be dangerous

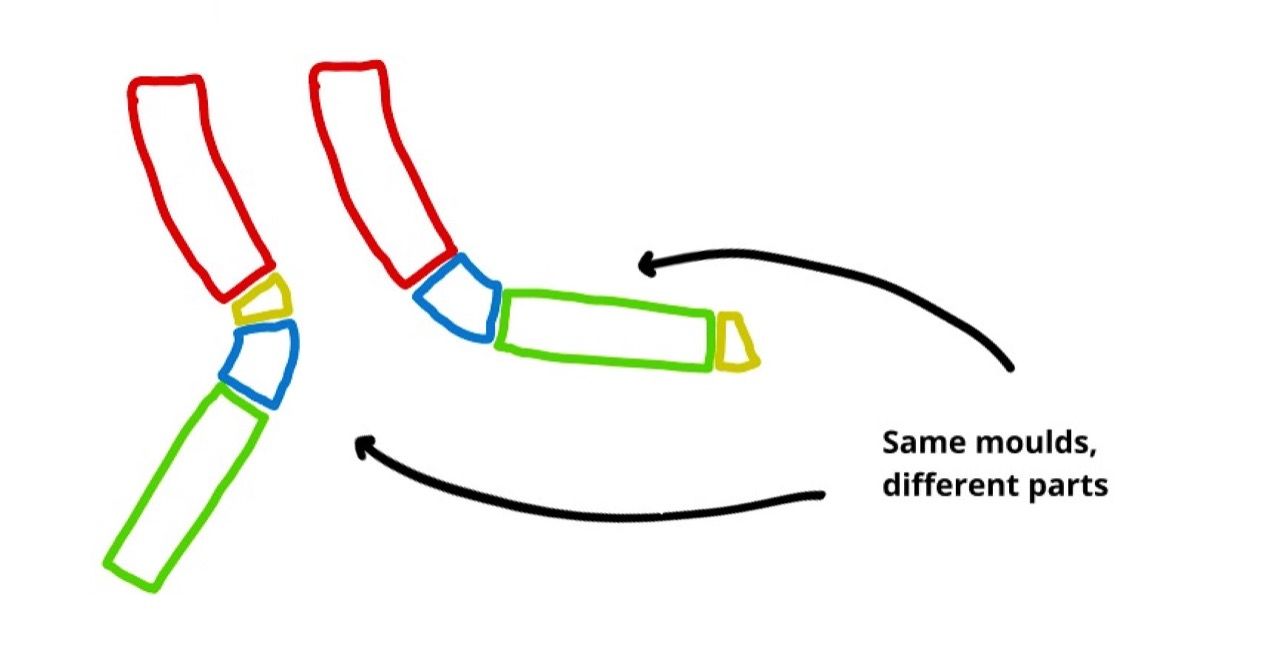

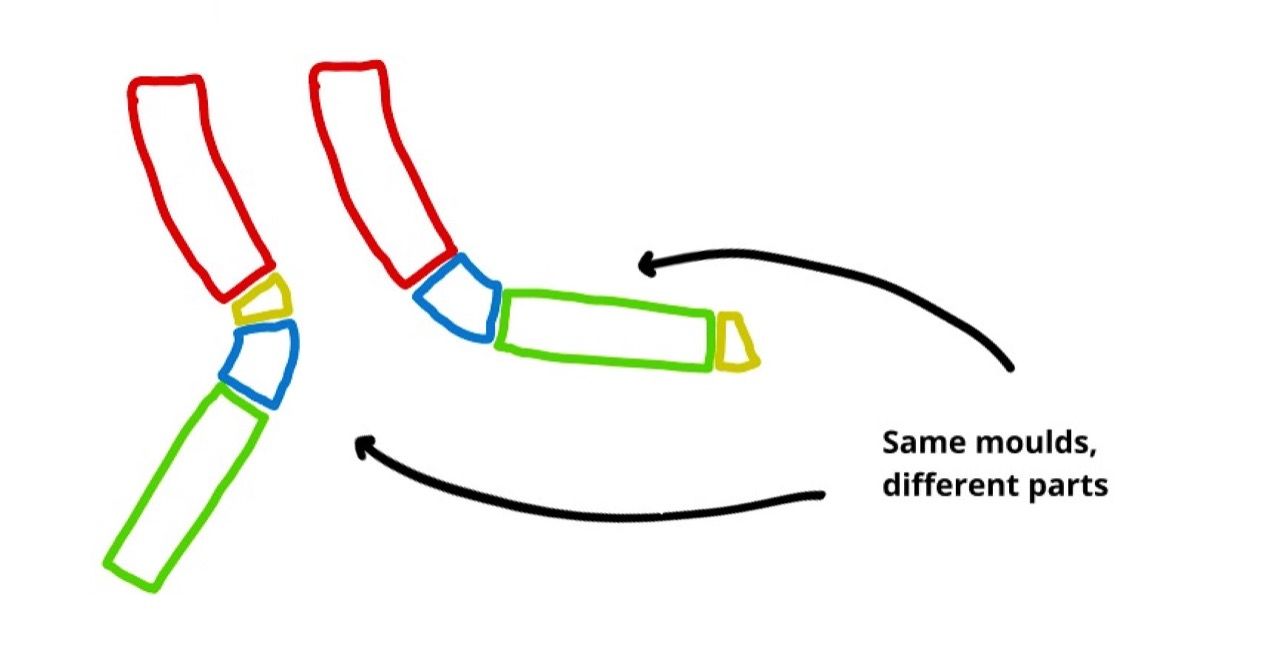

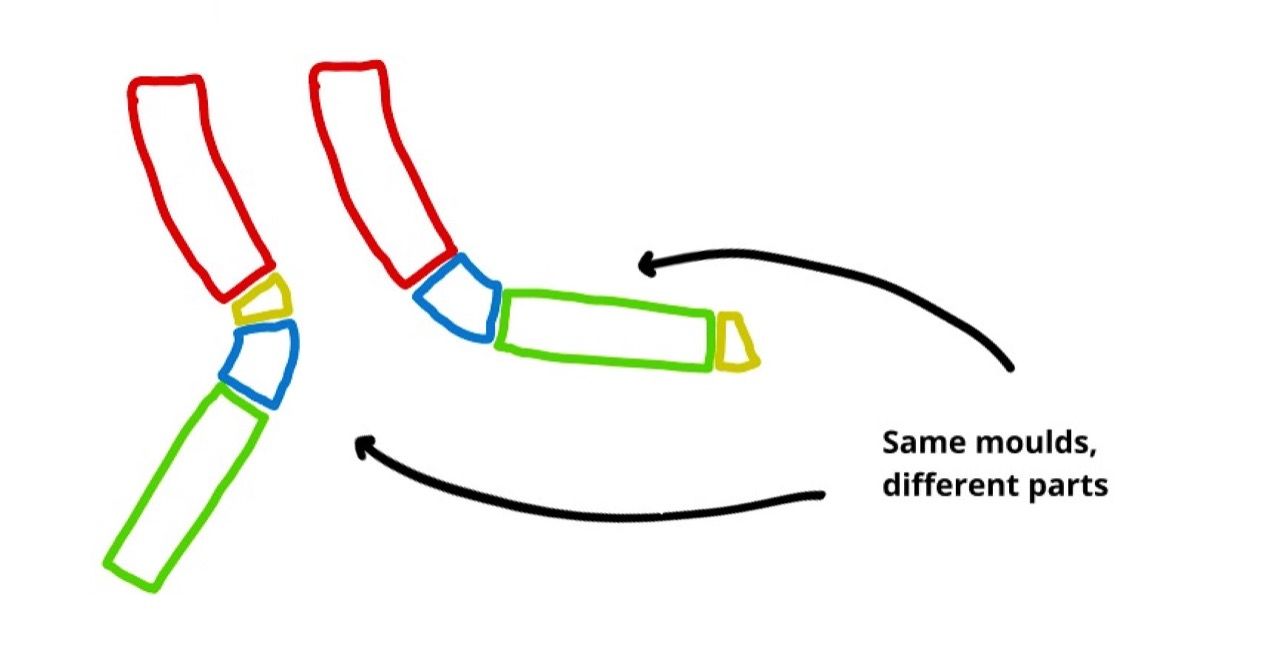

Concept 2 - Modular Moulds

Created 4yCreated over 4 years agoUpdated 4yUpdated over 4 years ago

Our second concept features a set of fixed mould segments that join together to produce all the required parts. These would be designed to bolt together and attach to our industrial extrusion machine.

This concept would allow us to make high quality parts as the segments would be designed to take pressure in order to squeeze out air pockets and cavities.

👍 PROS:

- can make high quality and accurate parts

- would work directly with the extruder

👎 CONS:

- requires more material and fabrication

- moulds might only be used once

- more expensive

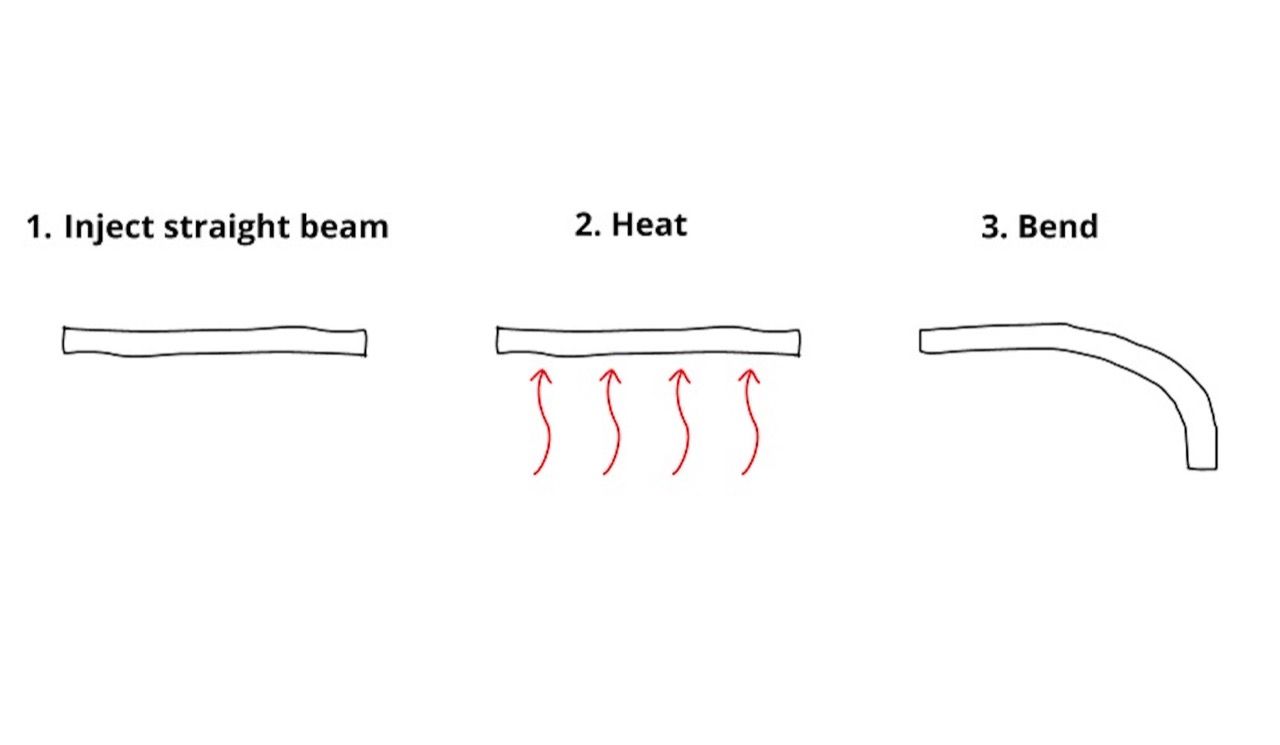

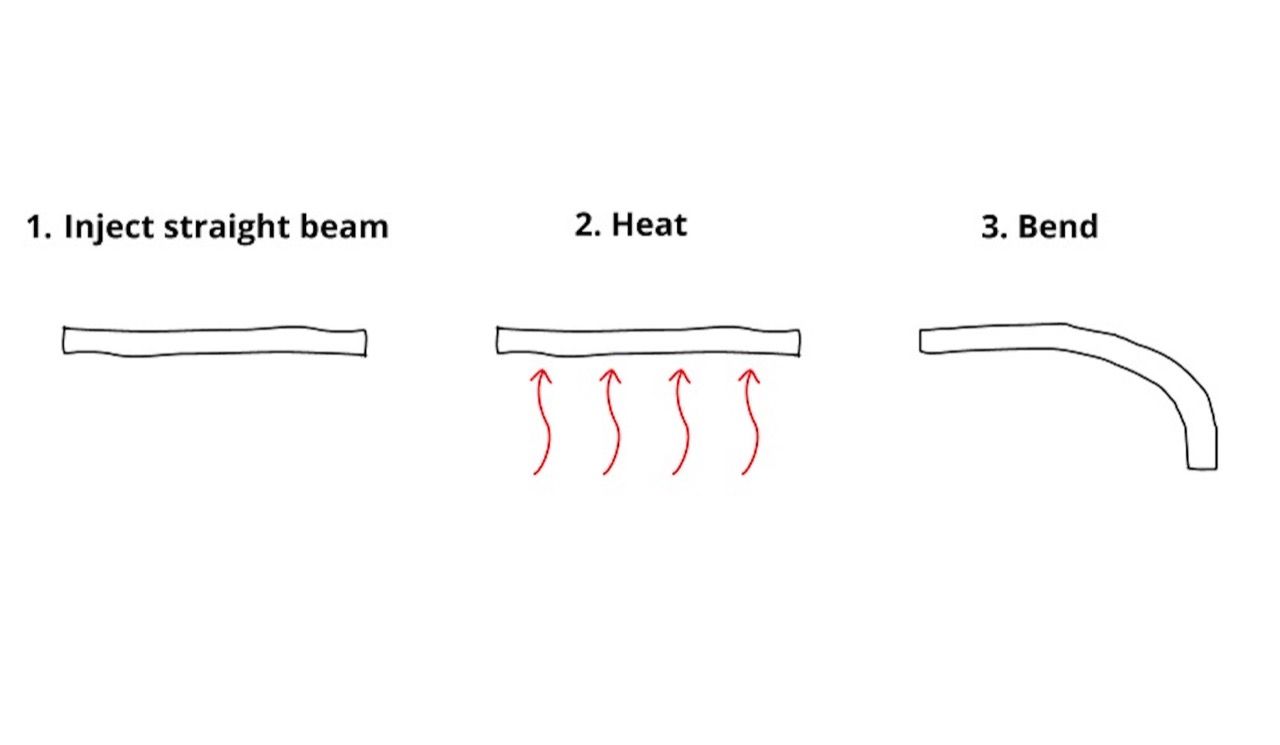

Concept 3 - Heat and Bend

Created 4yCreated over 4 years agoUpdated 4yUpdated over 4 years ago

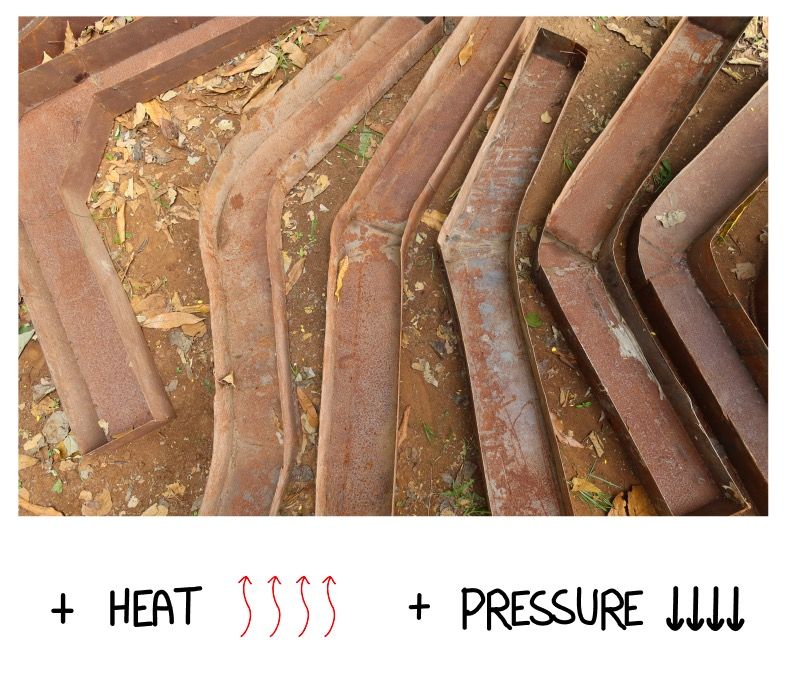

Our third concept departs from moulds completely as we would try and bend straight beams into our desired parts.

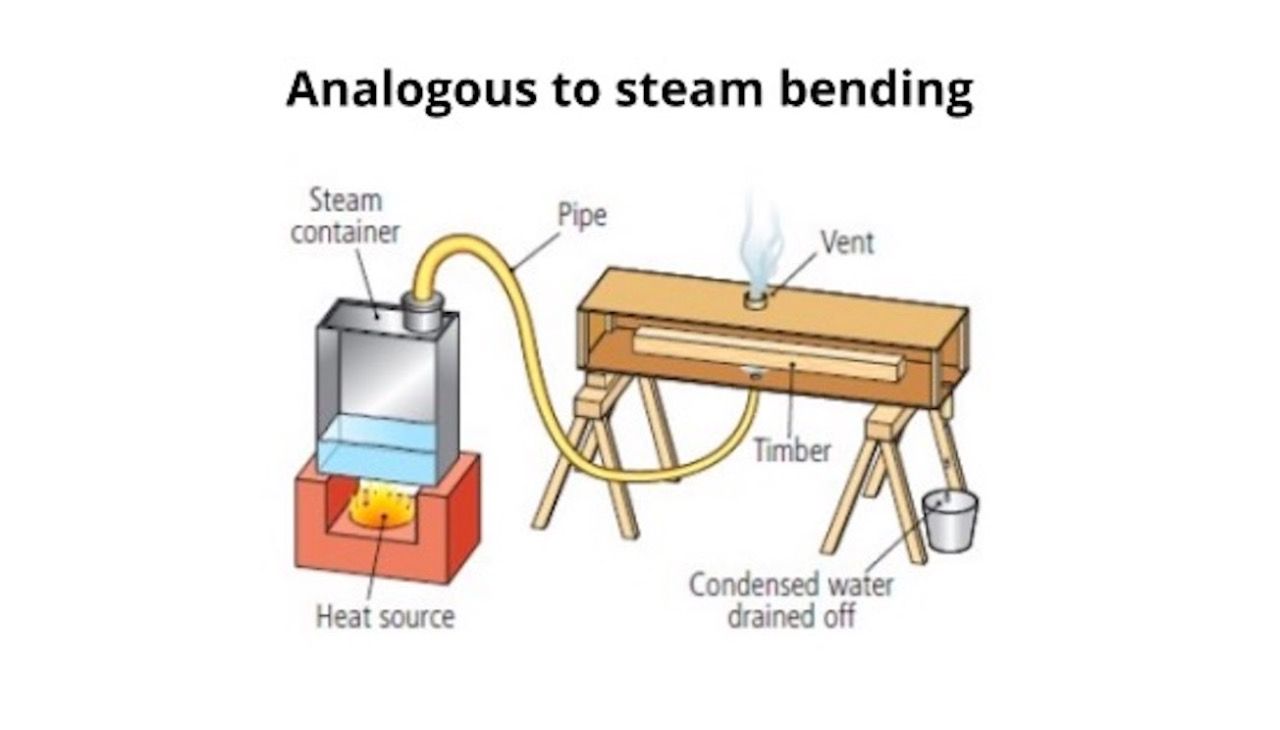

This is analogous to wood steam bending and we feel it aligns with the low volume and 'craft-like' nature of this project. It also has the added advantage of being applicable to many things other than boat building.

👍 PROS:

- doesn't require specific moulds

- can conntrol the quality of the material more effectively

- would be a universally applicable process (setup would still be useful after project concludes)

👎 CONS:

- untested on this scale

- bending may result in a decrease in material quality (needs to be tested)

Potential Application of Solar Power

Created 4yCreated over 4 years agoUpdated 4yUpdated over 4 years ago

These parts are big - that means we need a lot of energy.

If we just use an industrial extruder and inject into a very large mould, our plastic will start to solidify before our process is complete. So we need a way to keep our parts hot during the injection process.

We also have the advantage of being in Kenya where we can harness a lot of solar power.

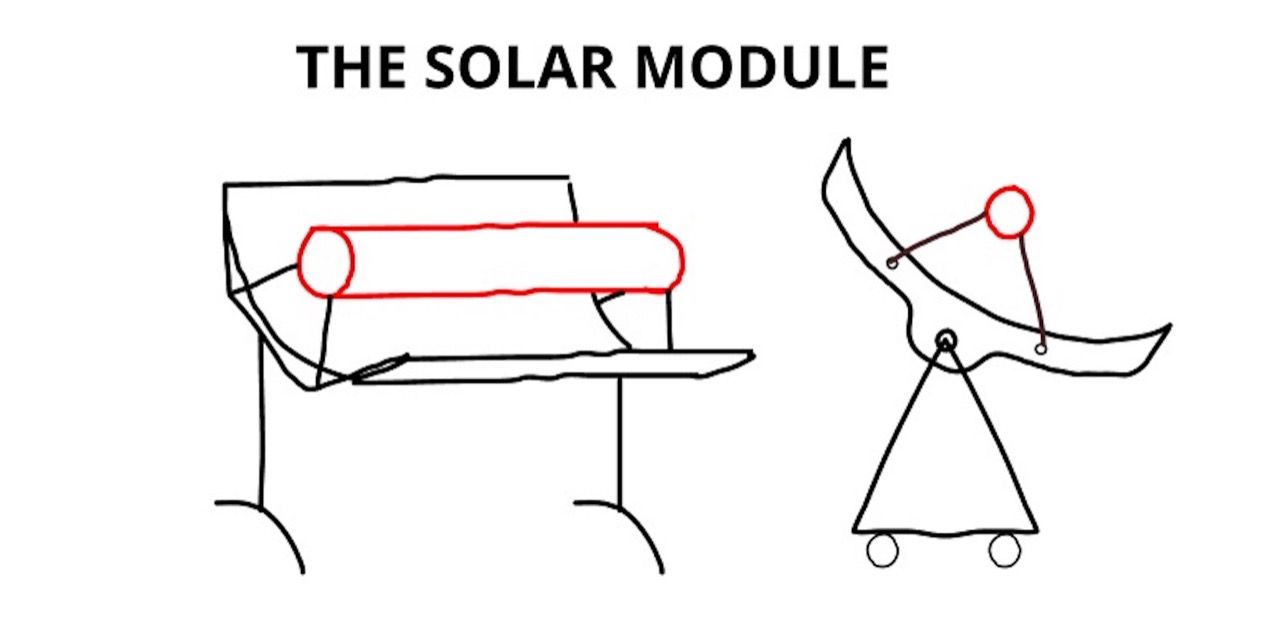

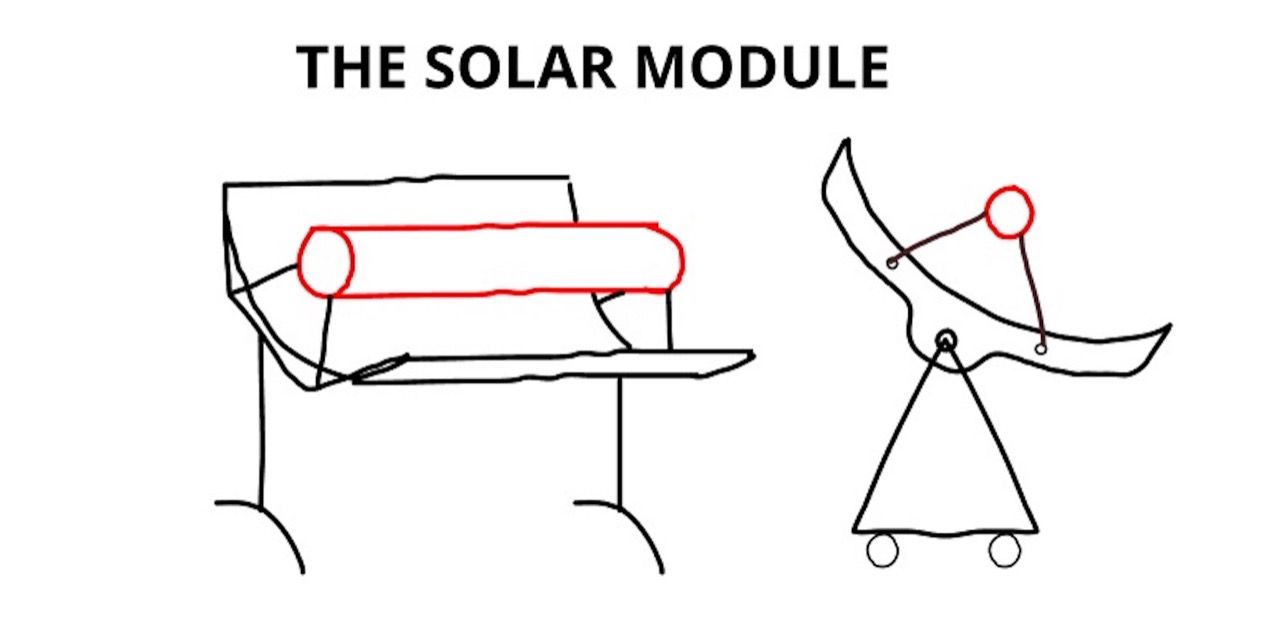

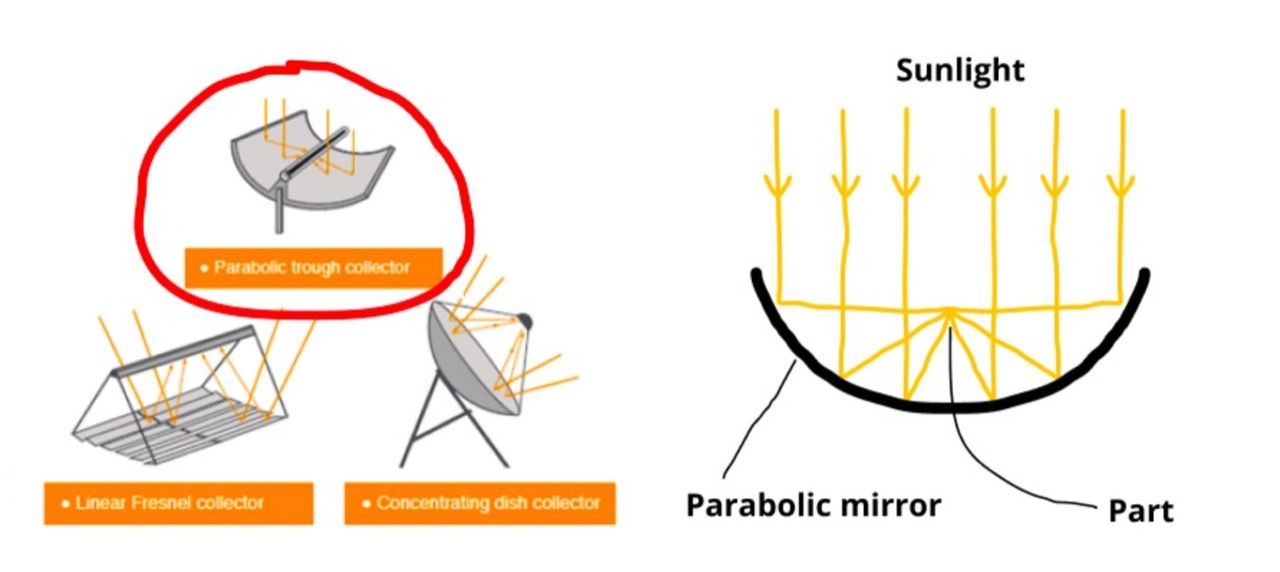

Looking into some various solar options, we identified the ‘trough’ solar configuration as the one most suitable for heating beams as it concentrates the light not at a point, but at an axis.

The Solar Module Concept

Created 4yCreated over 4 years agoUpdated 4yUpdated over 4 years ago

This is our concept for a modular solar plastic processing system.

It is made up of 1.2m lengths of a solar trough that we call the ‘solar module’ and each one has the ability to connect onto another to increase its length. Additionally each module has the ability to attach different kinds of moulds into its heating zone and these moulds can be coupled together to make parts from 1.2m up to any multiple of this (for example 10 modules together would make a 12m long part).

Building the solar module

Hello!

Okay, so this update is very delayed, but we actually continued building and testing the solar module.

Here the video of how it went - and how we cooked our first potatoes hehe!

TESTING the solar module with big plastic beams

Created 9moCreated 9 months ago

And here you go, our first tests with plastic beams.

In short, the volume of the mould was too big to actually MELT plastic in it.

BUT it did help to heat the mould in order to keep the extruded plastic HOT during the melting process.

Check out the video :)

3 years and upgrades later: WE MADE IT

Created 9moCreated 9 months ago

Hello good people!

SO. Fast forward from 2021 to 2024: We have actually managed to get funding for a bigger extruder (bigger than Precious Plastic sizes) and have made lots of tests, pushing the limits of recycled plastic!

We made the largest extrusion moulds I have ever seen (maybe the world has seen? Let me know if you know anyone doing similar scale pieces!) - and extruded big parts for the research towards building our BIG BOAT!

Here a quick teaser. If there is interest, we'll share some more details :)