Completed

Machines

Optical sorter -source files

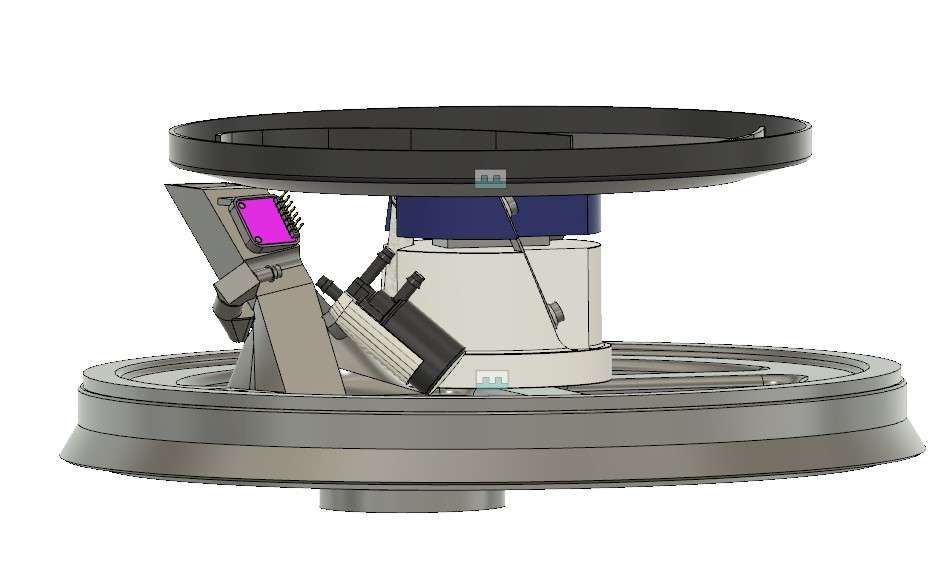

We are building an optical sorter with capacity of 1 - 10 kg/hr. Here we present a prototype of a portable optical sorter that fits on top of a 5 gal. bucket and sort 1 kg/hr. per channel (up to 6 channels). It sorts according to color, RGB, as programmed by the operator. It can sort for multiple colors (e.g., blue and green out of a complex mix of colors). This project was done in collaboration with Diproinduca https://www.diproinduca.com/researchother machinesorting

More Information

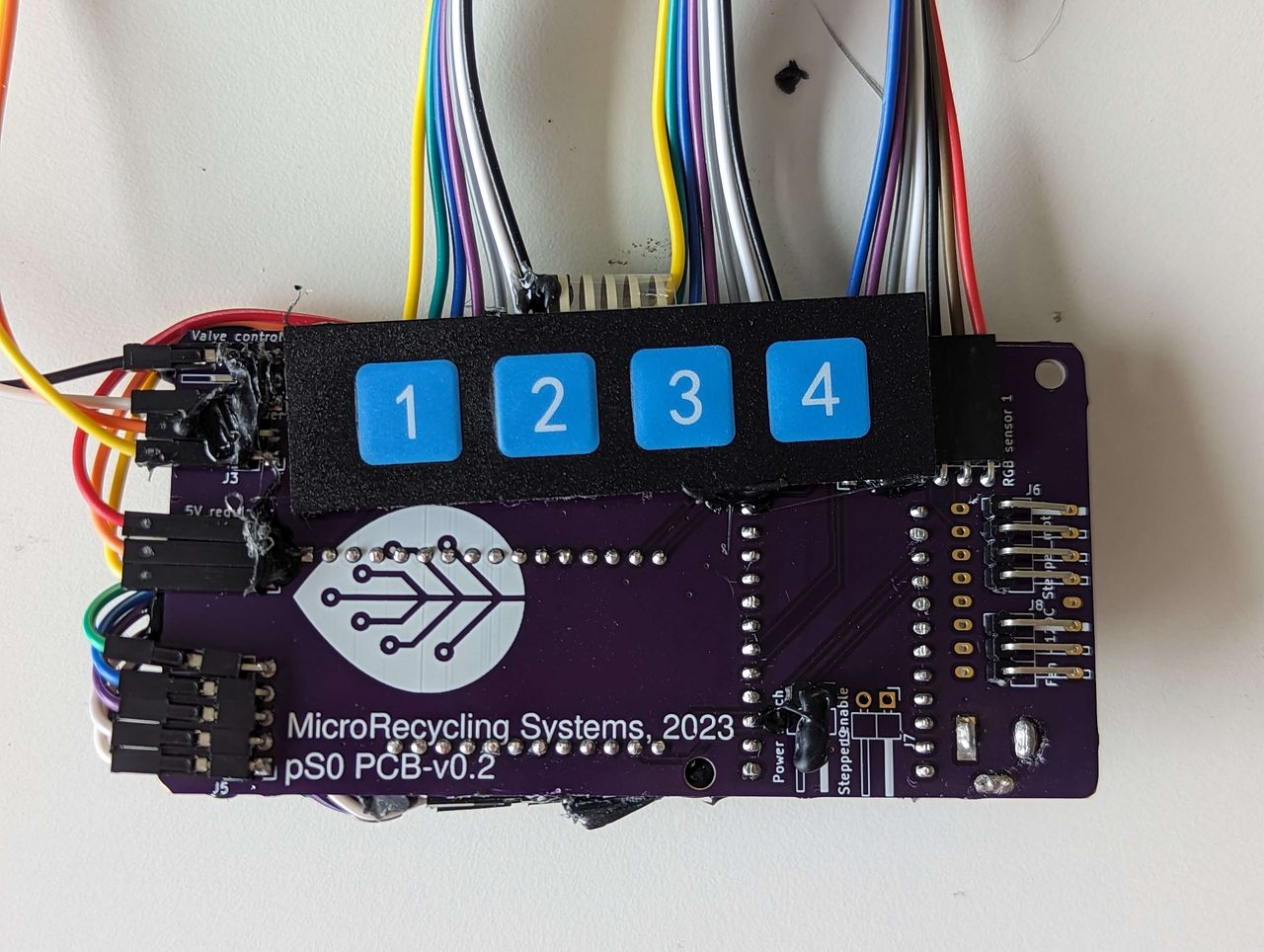

Electronics for the pS0 portable sorter

Created 11moCreated 11 months agoUpdated 10moUpdated 11 months ago

The pS0 portable sorter uses off-the-shelf PCB modules, all wired together in a single PCB. The components are Adafruit Feather M4 microcontroller, 1 - 6 pcs. TCS34725 RGB light sensor, TCA9548 I2C multiplexer, and 1 - 6 pcs. MOSFET to drive the valve servos.

Files are from KiCAD 6.0.

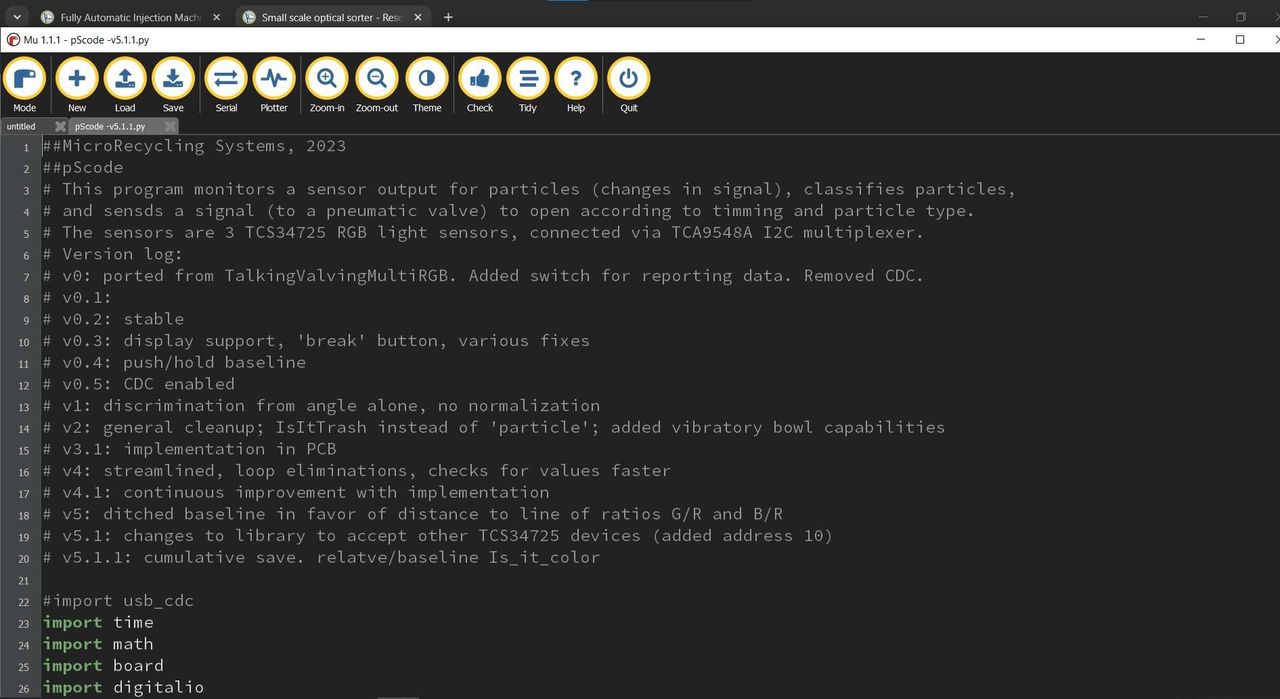

Firmware for the pS0 portable sorter

Created 11moCreated 11 months agoUpdated 11moUpdated 11 months ago

The pS0 portable sorter uses firmware written in CircuitPython 8 or compatible. It can work with up to 6 RGB sensors, each paired to a valve signal output. The TCS library is modified to not wait between queries, thus speeding up the process loop significantly.

The code can also be found here https://github.com/Turtle49/pS0

Mechanical design for the pS0 portable sorter

Created 11moCreated 11 months ago

The pS0 portable sorter was designed using Autodesk Fusion 360.

97% sorting accuracy

Created 11moCreated 11 months agoUpdated 10moUpdated 11 months ago

pS0 is able to filter out 97% of the targeted particles.

Empirical design

Created 11moCreated 11 months ago

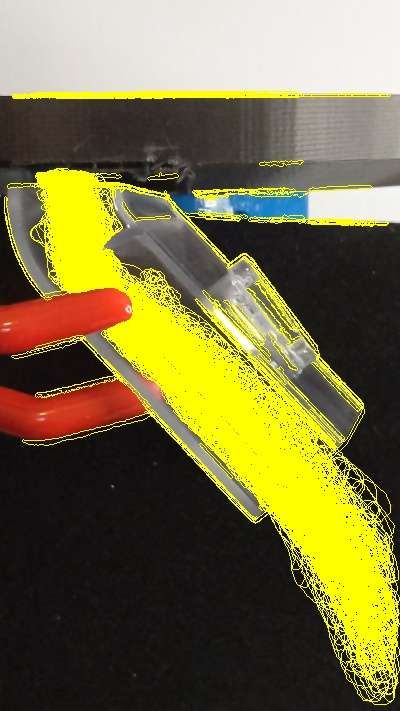

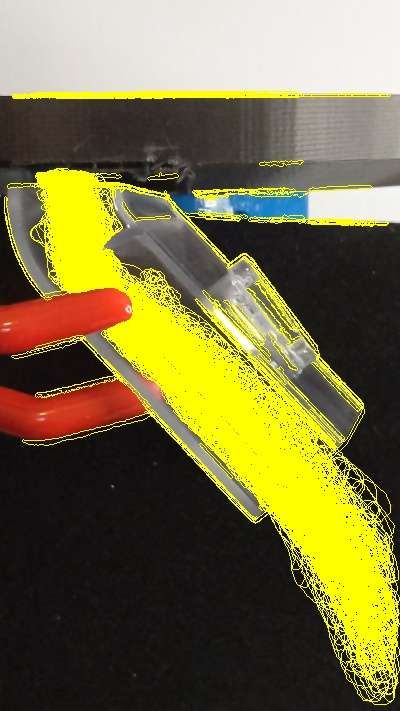

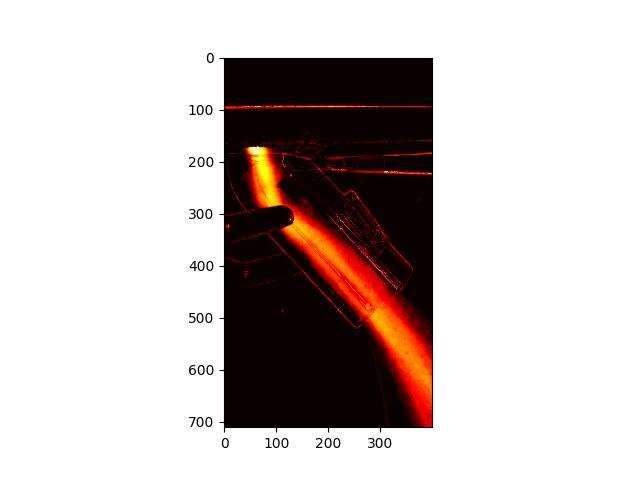

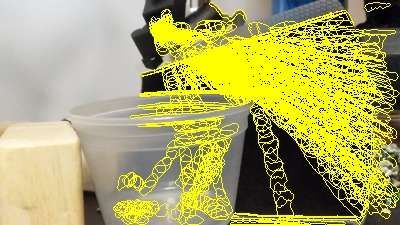

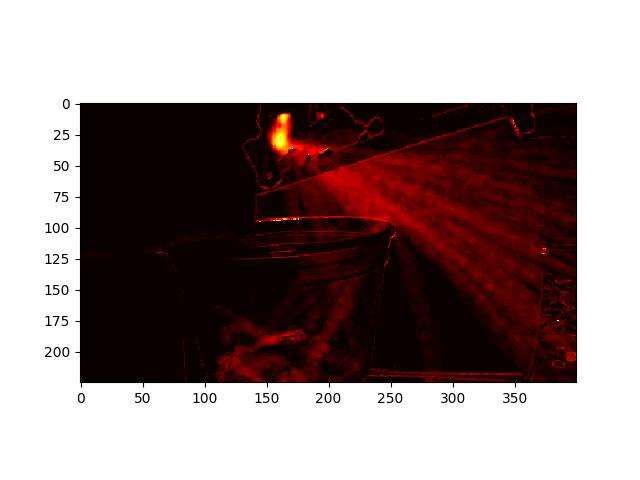

We used a trial-and-error loop, where we 3D printed the channel, tested it, analyzed video of it, and refined our design.

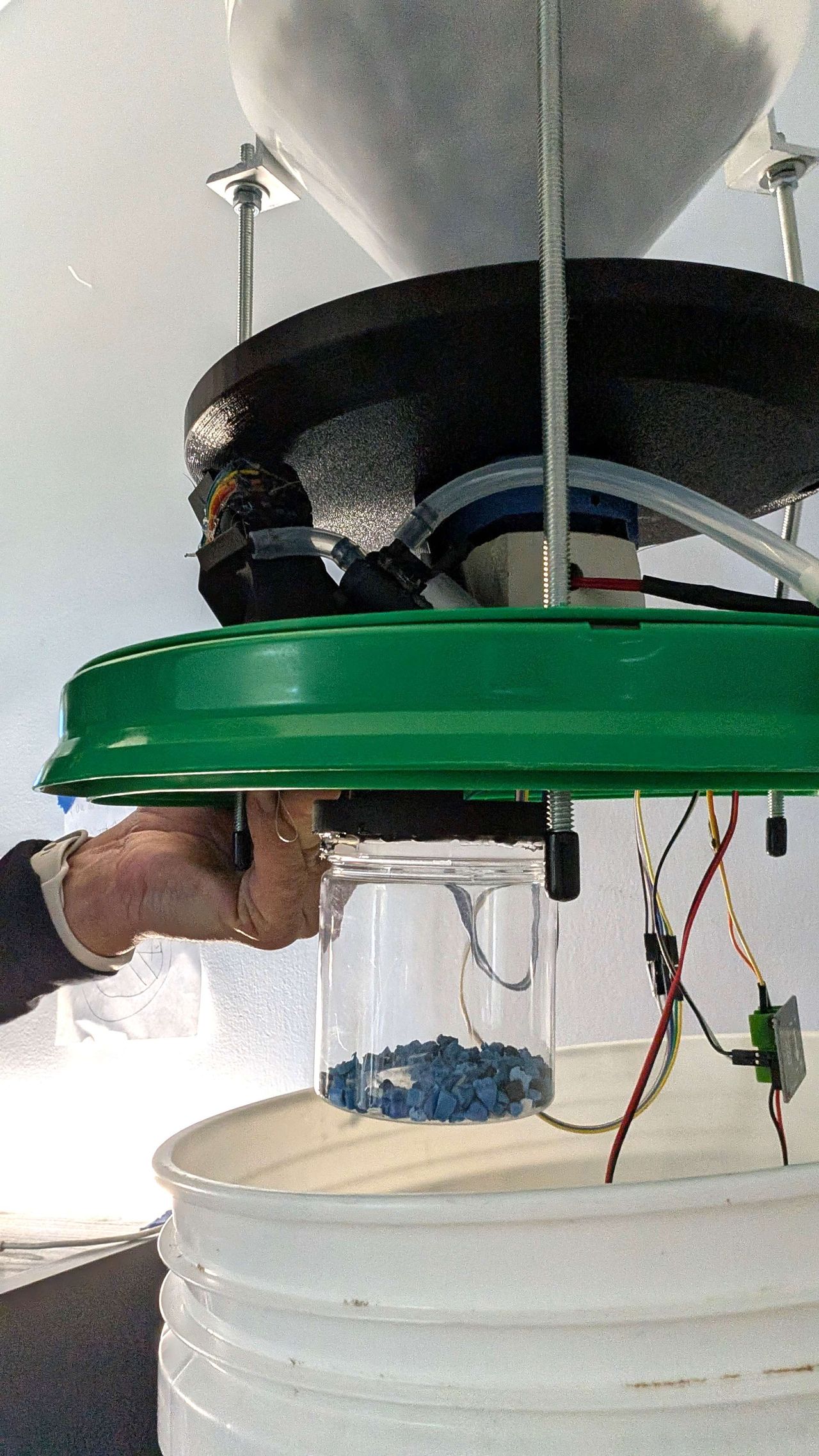

Integrated system

Created 10moCreated 11 months ago

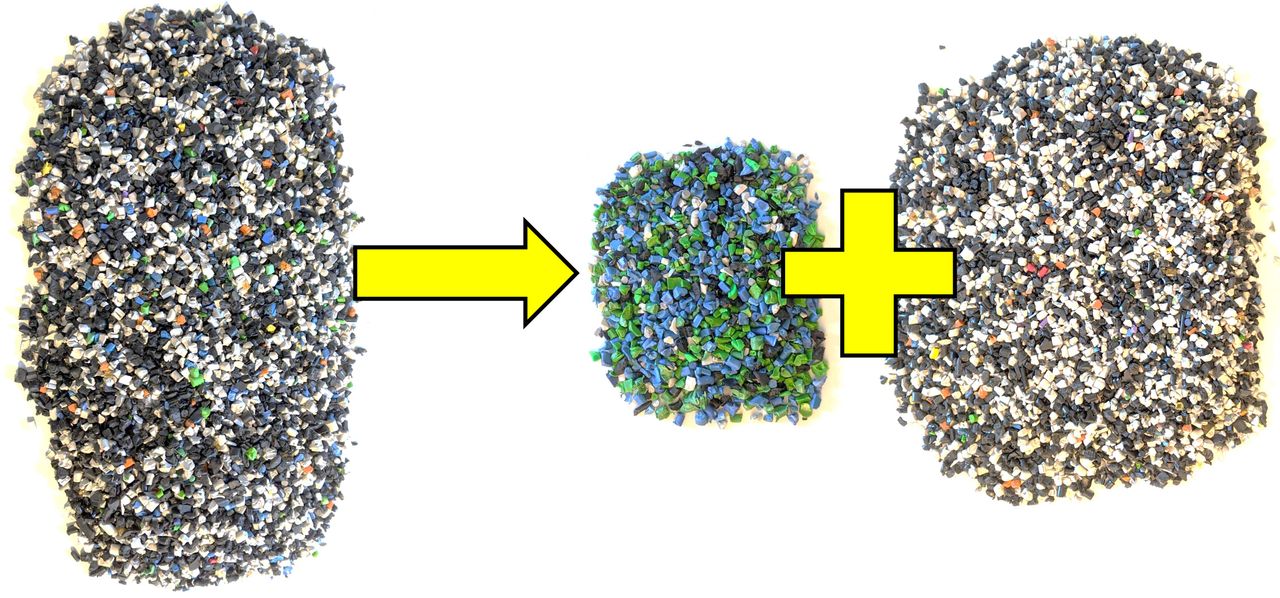

We finally integrated the entire system over a 5 gallon bucket. To operate it you need 100VAC and and compressed air to 15 psi. 0.5 Kg can be loaded at one time through the top of the system. A vibratory feeder moves particles in a file towards the sorting channel, where the sensors scan every particle that falls through it. If a particle is of interest, then compressed air is used to set the particle aside. In the case below we were looking for blue particles.

pS0 in action

Created 10moCreated 11 months ago

The optical sorter pS0, an experimental prototype for sorting solid scrap, is sorting plastic (PLA) scrap of different colors, separating blue particles from the mix. Here we see a closeup of the particles as they are about to enter the sorting channel, and then a peek to the inside of the 5 gallon bucket.

Optical sorter in action

Created 10moCreated 11 months ago

Optical sorter pS0 is separating blue particles from a material stream of PLA particles, 5 mm in diameter.