HfG-Jaipur Knee Prosthesis 1.0

PP

More Information

1

HfG-Jaipur Knee Prosthesis 1.0

Our goal is an Independent worldwide production of functional prosthetic components.

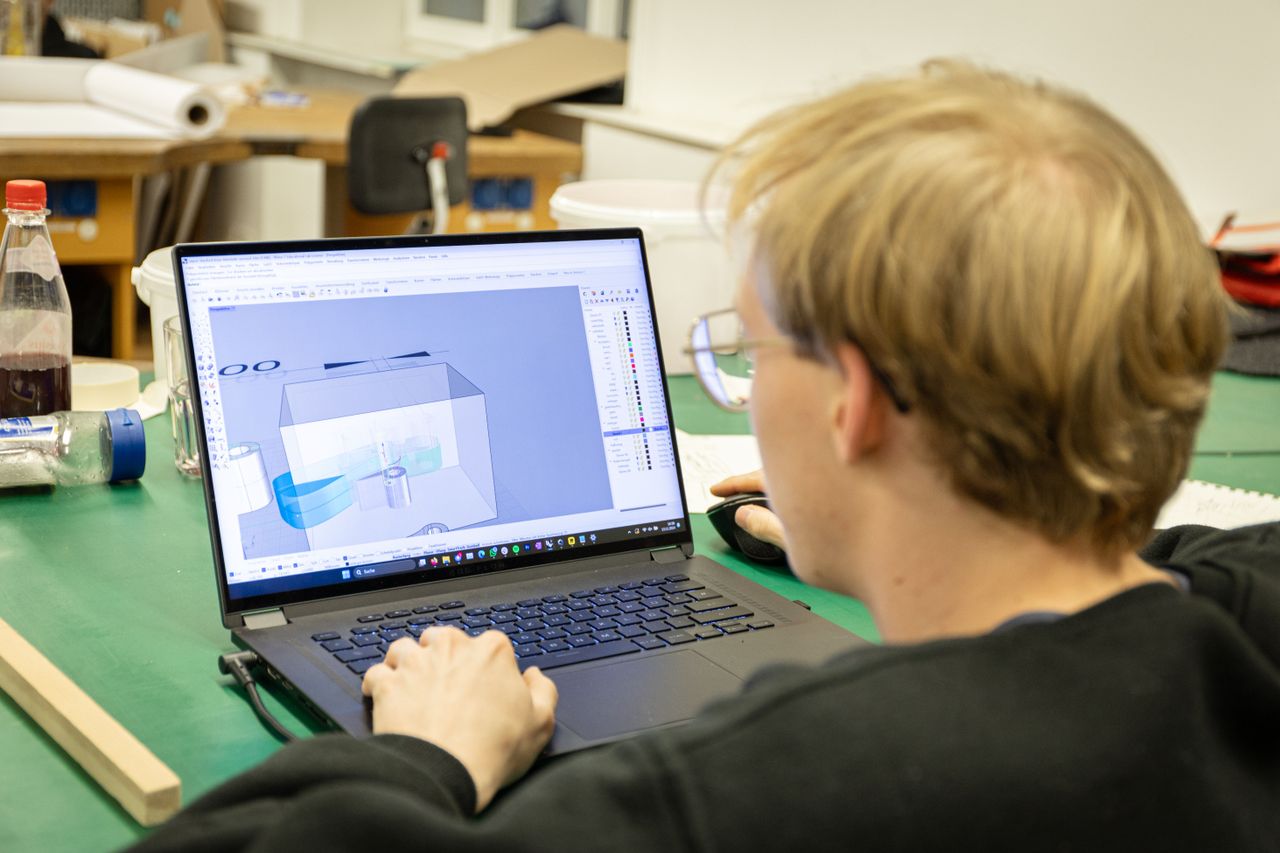

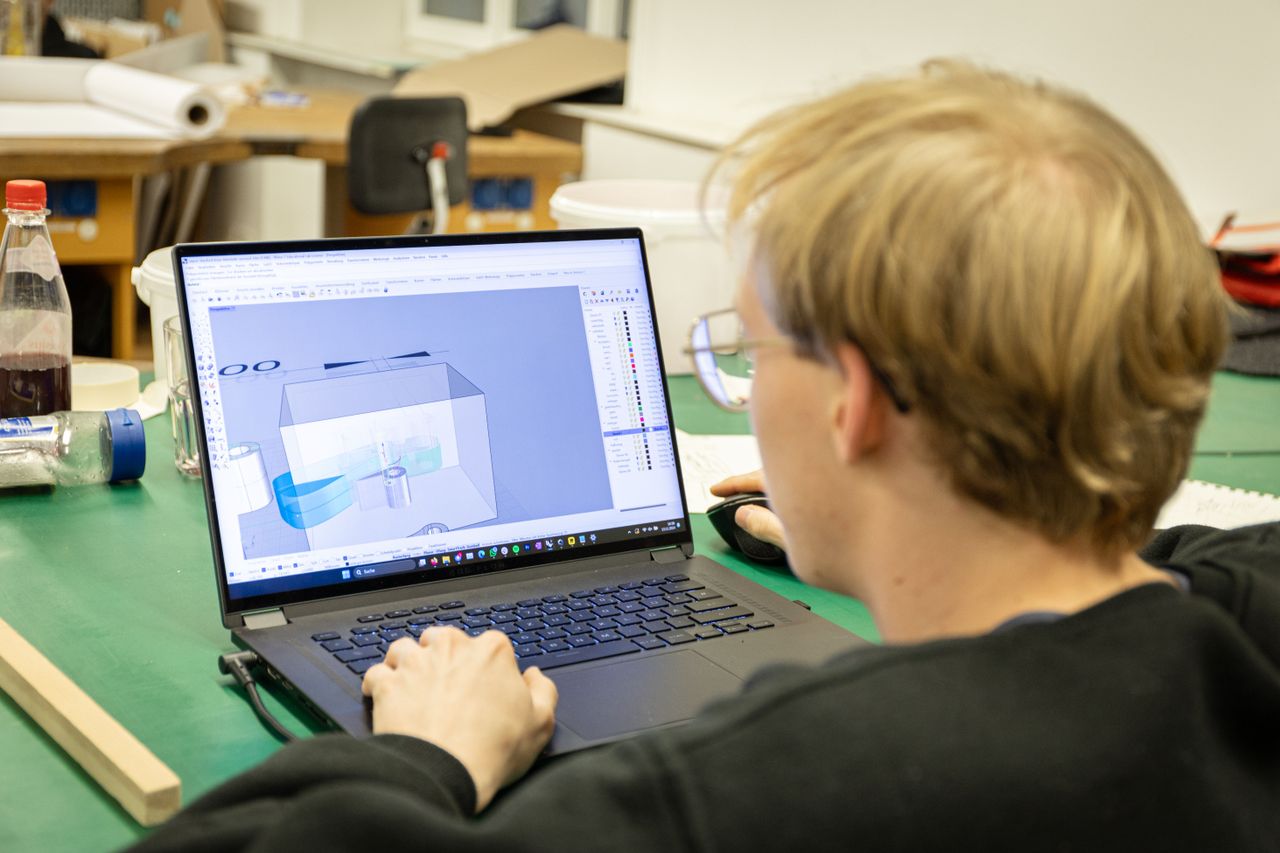

The project was created during interdisciplinary work at the University of Design

Schwäbisch Gmünd and is an attempt to enable people who have lost the ability to

walk to walk again.

It’s the first prototype of our Knee Prosthesis which is based on PP. In the future

prototype version we wanna create products which are based on PET and also for

other parts of the body.

2

The HfG-Jaipur Knee is based on the Stanford Jaipur Knee

The HfG-Jaipur Knee Prostheis is based on the “The Stanford-Jaipur Knee.”

The Stanford-Jaipur Knee is an invention designed by the Stanford University, USA,working with the BMVSS team. The Stanford-Jaipur Knee has been hailed by Timemagazine (issue of November 23, 2009) as one of the 50 Best Inventions of the Worldin the year 2009.

We took this project as an example and created a prosthesis based on PP. This savesas many materials as possible and therefore also takes the environment, climate andresources into account.

Please note that this is the first prototype. This mechanical knee is not ready for realuse. It is a HfG- study and starting point for further developments.

3

Requirements

Created 1yCreated about 1 year ago

Leftover plastics (sorted by color and type) (In this first example, polypropylene (PP) was used as the starting material. In the future, polyethylene terephthalate (PET) willbe used to ensure the durability and resilience of the prosthesis. This also applies toall other parts planned for the future, such as the base and the socket.)

Plastic shredder

Injection molding machine

5x Injection molding tools

4

Preparing Your Plastic

Created 1yCreated about 1 year ago

In order to press the plastic into the mold, it must first be shredded into granules. Use

the plastic shredder for this. Depending on the type of shredder you have, you will

need to shred the plastic 3-4 times.

5

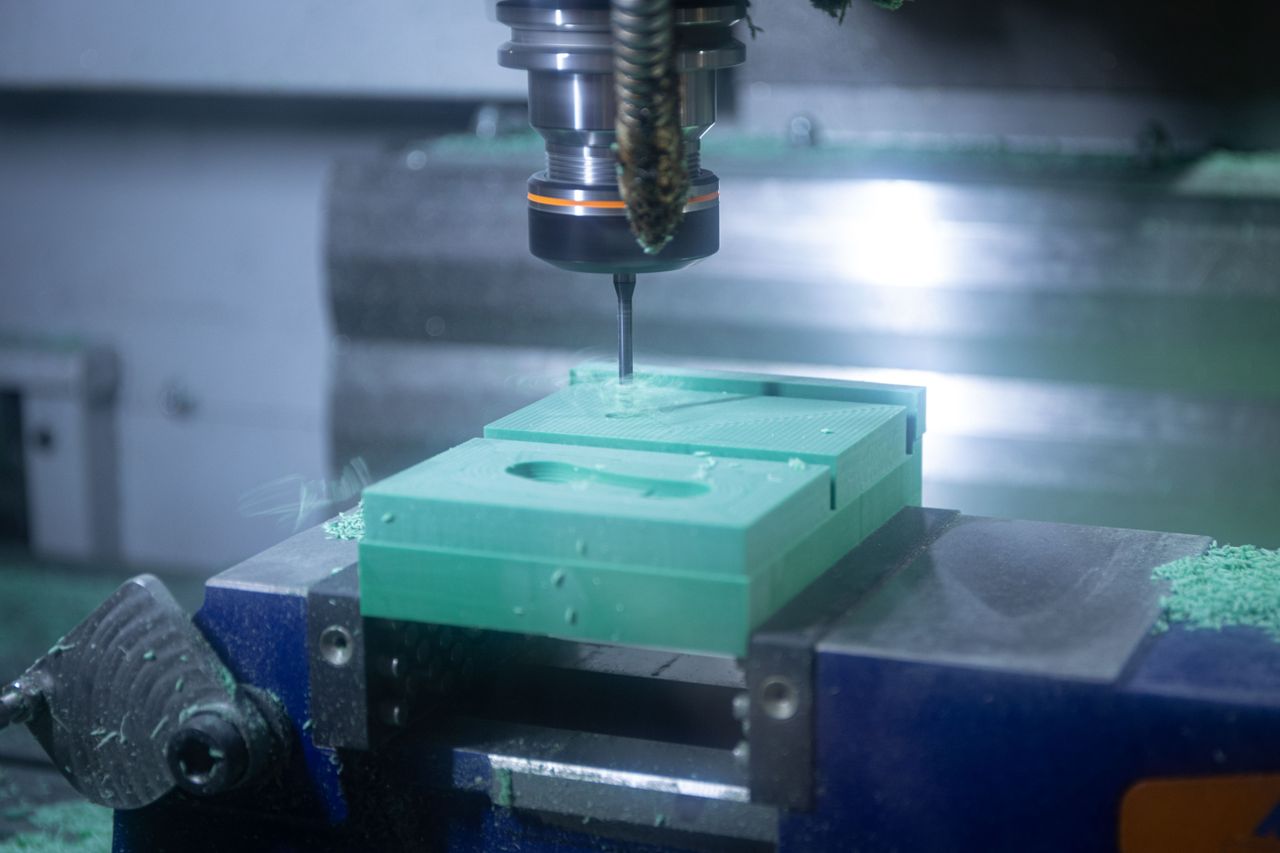

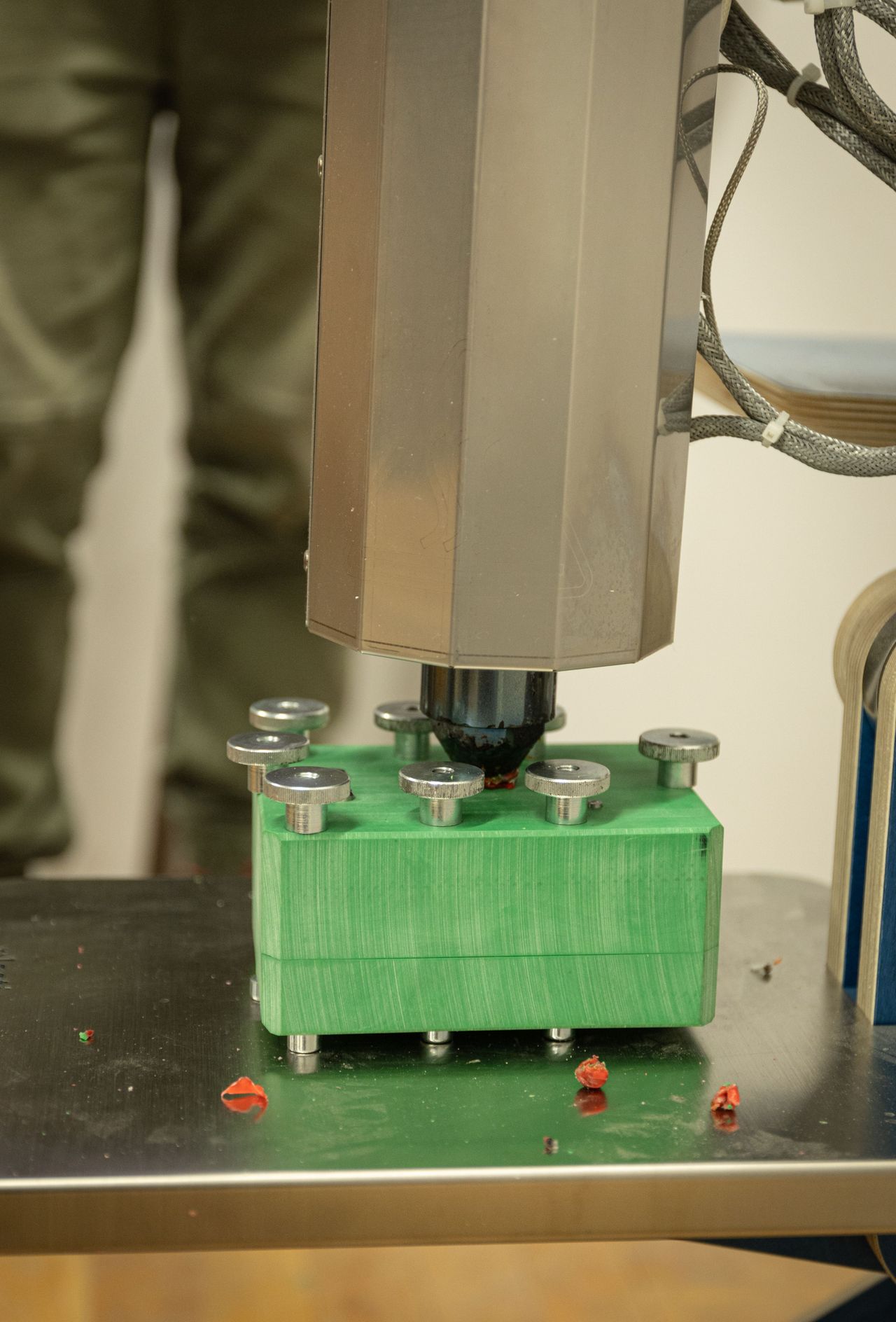

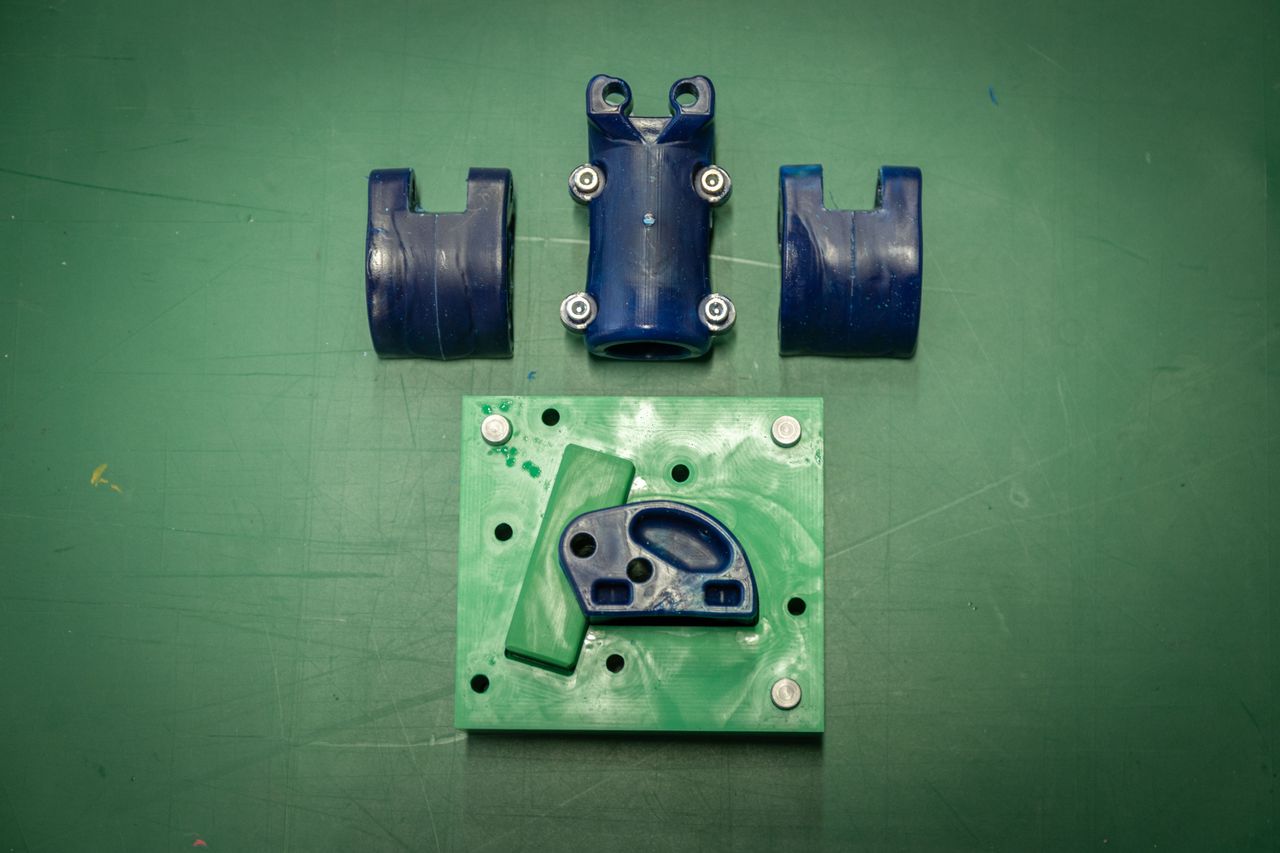

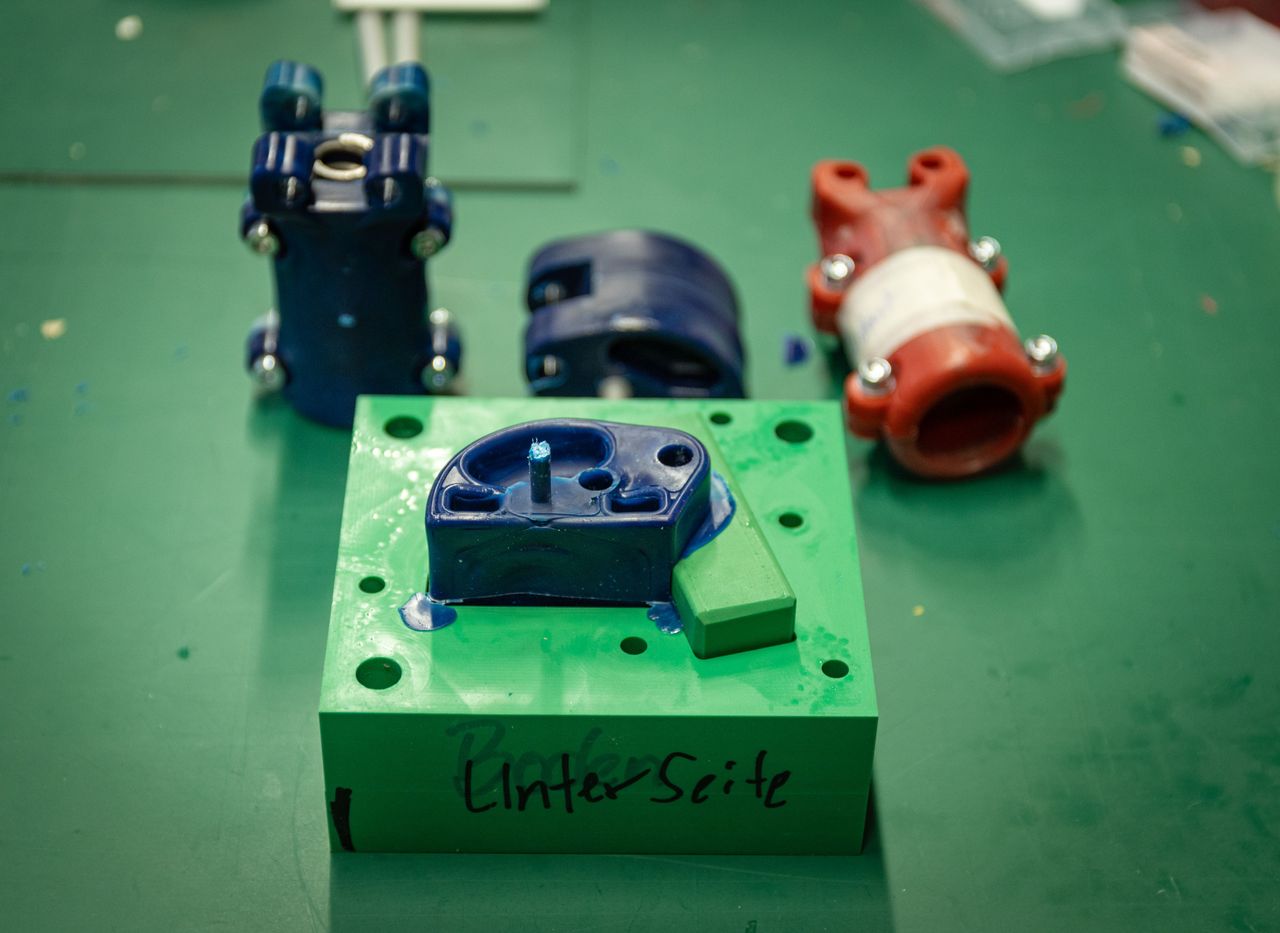

Injection into the mold

Created 1yCreated about 1 year ago

Fill the injection molding machine with the shredded plastic and wait until the plastic

has melted evenly.

Insert the mold under the injection molding machine and inject the plastic mass evenly

into the tool.

6

Let cool

Created 1yCreated about 1 year ago

Let the plastic cool down for a while and then remove the part from the mold. Repeat

the steps until you have made all the parts.

-193d6973c5a.jpg?width=1280&resize=contain)

7

Assembling parts

Created 1yCreated about 1 year ago

Once you have made all the parts, you can now put them together to create the

finished prosthesis. Please note: Some parts still require holes to be drilled in order to

screw the parts together.

8

HfG-Jaipur Knee & HfG Team

Created 1yCreated about 1 year ago

The team that worked on converting the Stanford-Jaipur prosthesis into injection

molded PP:

HfG Schwäbisch Gmünd

University of Applied Sciences

www.hfg-gmuend.de

It is an association of the faculties:

Product Design, Interaction Design, Communication Design and Digital Products

The project was supervised and supported in Nov. 2024 by:

Prof. Gerhard Reichert

Andreas Belthe - Method and Research Learning Lab

Jens Kause - workshop master – Machining & Laser

Students (alphabetical):

Anna Weinstein

Anton Pelezki

Clara Butkovic

Daniela Ciochina

Dimitri Wagner

Franz Anhaeupl

Gianni Pighetti

Julian Vogelsang

Julius Schoch

Maximilian Pfandl

Selamawit Gegziabher

Please note that this is the first prototype. This mechanical knee is not ready for real

use. It is a HfG- study and starting point for further developments.