Can we inject products from old water pipes

injectionLDPE

More Information

First injection tests

As you might have seen in the first update on this research module https://community.preciousplastic.com/research/how-does-the-shredder-pro-by-weima-behaves we shredded some LDPE old water pipes from Project Kamp and now we want to test melting them to see if we can transform it into something new!

First thing was to try melting a small amount in the injection machine and since we knew we were working with PE we set the machine to 240ºC so that we could check the consistency and see if it needed more or less temperature before injecting.

Fortunately, it looked fine based on our experienced injecting and since we know PE in general is a plastic that can be a little tough to inject, we tried with some single-cavity moulds we had laying around in our workspace.

Here are a few things we noticed when melting the pipe:

- When we were melting the plastic, we noticed a particular smell, a bit strong. Similar to the smell we've gotten when melting fishing nets. We believe this is because of the water this plastic absorbed over the years and when melting it, some mixed gases got released. We are not sure of the dangers of these gases (let us know if you do), but we were sure to wear our PPE and keep the space ventilated.

- We also noticed that while we were waiting for the plastic to be melted before injecting, that the plastic started "bubbling up", so we were making sure to not fill the barrel to the top, so there was some space for the "bubbling". We also believe this is due to the trapped moisture in the plastic. We've seen this in the past when washing plastic and injecting without using a proper dryer.

Besides the stinky smell, the injection went super well, the product is very flexible and feels strong.

In the next update we will be testing some more interesting moulds :)

-19362f03341.jpg?width=1280&resize=contain)

-19362f03341.jpg?width=1280&resize=contain)

-19362f03341.jpg?width=1280&resize=contain)

We got some cool molds!

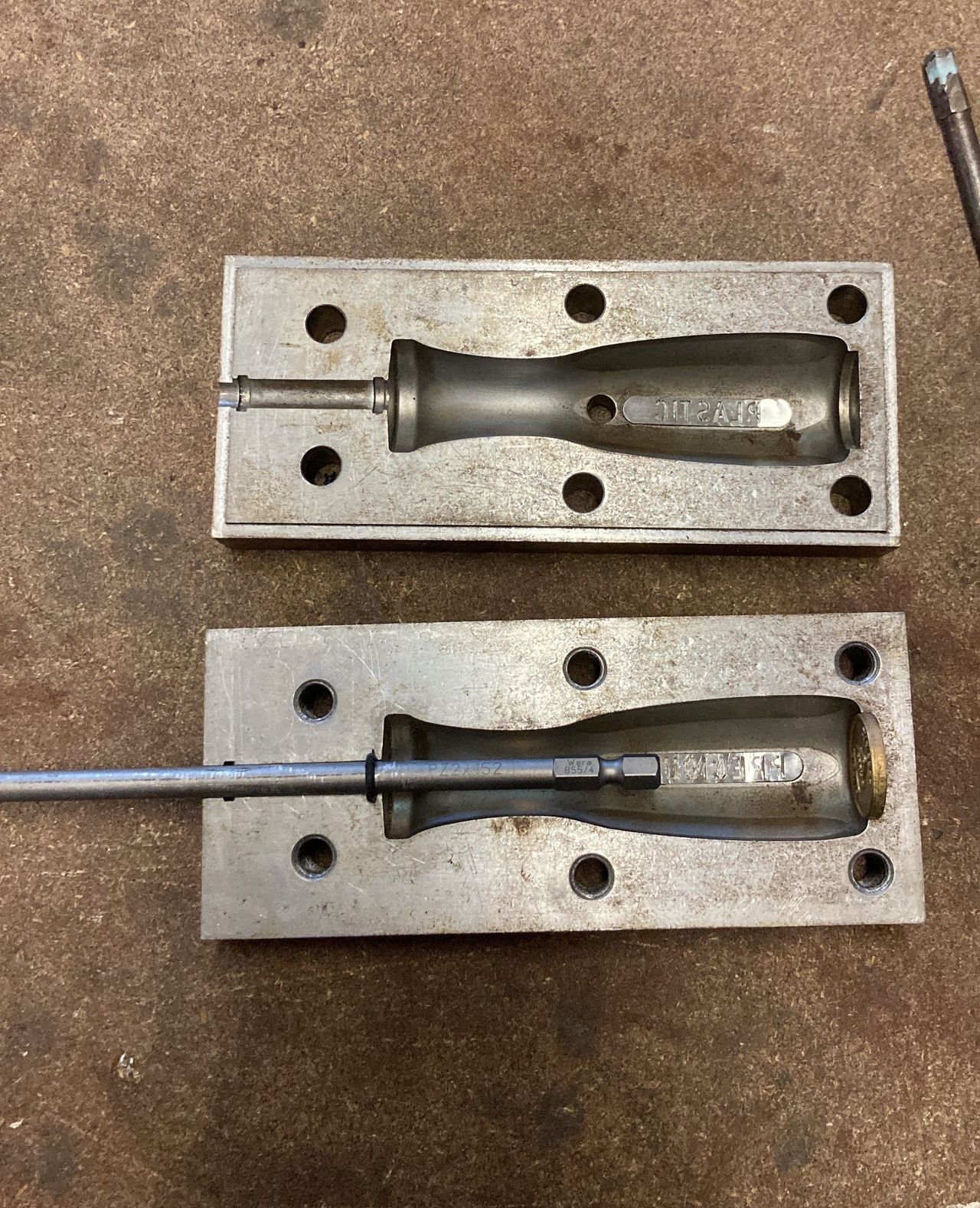

Our friends @johannplasto and @fair-enough lent us some cool molds for us to do some more interesting injection tests.

We got screwdriver, peg and hook molds and we also had a tile mold in our workspace to add more variety :)

Injecting into multiple cavity molds

Created 1yCreated about 1 year ago

We were interested to see if we could easily inject into more complex moulds.

We first tried the peg mould and we failed. We believed it's because as PE is not as liquid as PP (and the mold was designed to be used with PP), so it was cooling down before it could fill the mold.

Then we tried with one that was a bit less complex, the 4-cavity hook mold and it worked really well in the first trial :D

Testing the other molds

Created 1yCreated about 1 year ago

Since we had a successful trial with the hook mold we decided to try the other molds.

We had no issues at all making screwdrivers and tiles. We believe this material works best when the product that are a bit more "chunky" since it doesn't need to be so "flowy" to work.

It feels very nice in hand and also feels very strong and durable. The aspect is smooth and very shiny.

Hook production

We wanted to make a small production of 20 hooks for the Project Kamp supporters :)

While doing this we paid close attention to how the machine and mold behaves.

Everything went well and felt normal, we just had a few underfilled injections, not many, maybe around 2-3 injections out of 7.

We think this happened because sometimes we didn't have enough material in the barrel when injecting (even though we thought we did). This is because of the "bubbling" of the plastic mentioned in update 1. So, even if it looked full, it was not, so after we realized, we started compacting the plastic several times during the melting process to make sure we filled the barrel completely.

But other than that, it worked really well and we are very happy with the results :)

-1933c4280b2.png?width=1280&resize=contain)

Conclusions

To wrap up this module, we encourage you to explore recycling unconventional plastics. We understand it can be a little scary sometimes, especially when the material’s origin or composition is unknown. However, by following all safety protocols, starting with small-scale tests, and closely monitoring your parameters, you can gain very valuable insights while taking care of a waste stream that others may avoid.

So, in conclusion, yes! We can inject old LDPE water pipes and transform them into something useful, beautiful and long-lasting :)