Surf Fins Mould

Preciós Plàstic València will show you a simple technique to make a mould for producing recycled surf fins. This include how to prepare the 2D/3D model for laser cutting, how to inject the plastic waste, and how to finish the product. In this folder you will find: 3D CAD (.step and .f3d) Laser cut files (.dxf) Blueprints (.pdf)productinjectionPPmould

More Information

1

Design mould

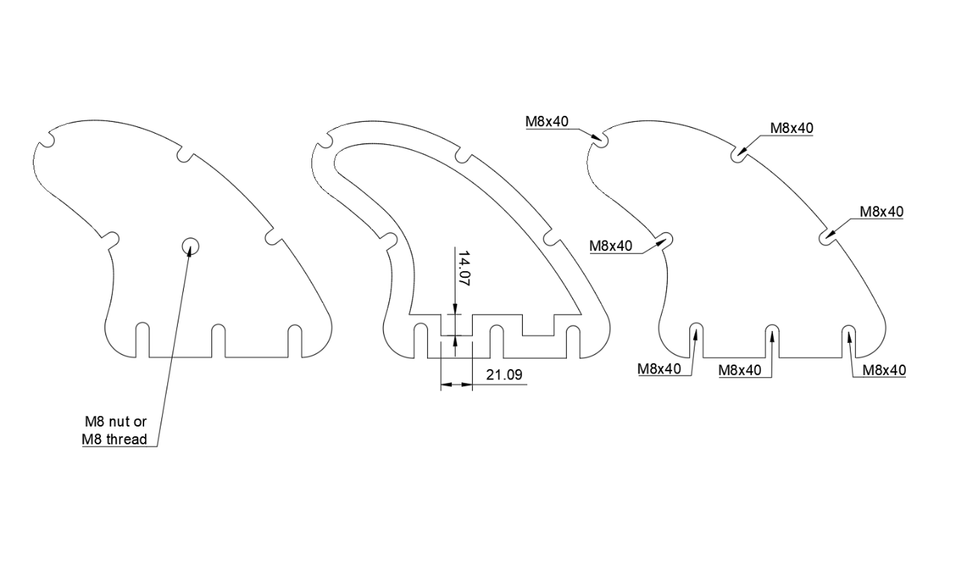

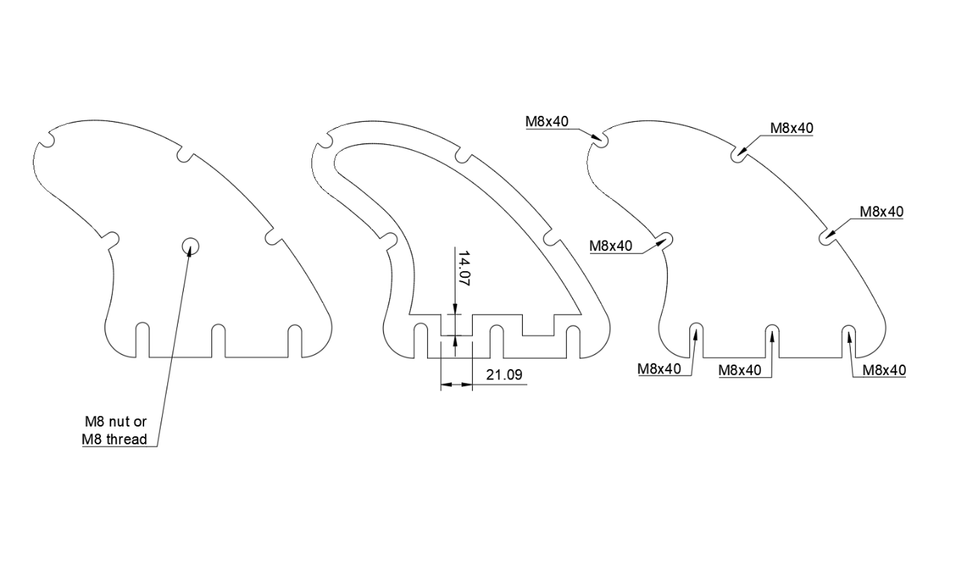

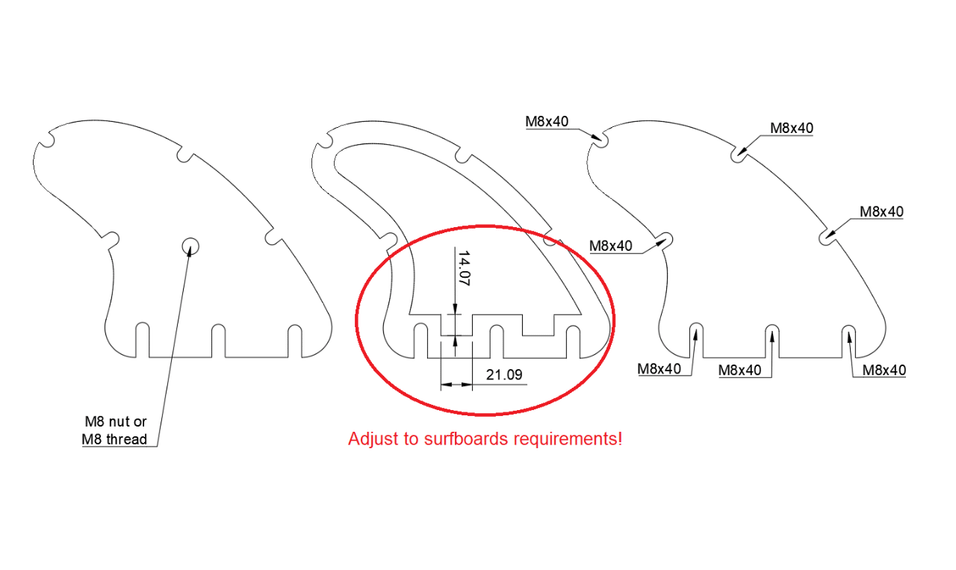

As a first step you have to design the correct dimensions for your fin, your design must meet the requirements of surfboards.

The most important dimensions are the area that connect the fin with the surfboard, could have dimensional variations. Check the width, height and thickness (thickness comes from the size/thickness of the stainless steel sheet, in our case 6mm). The top and bottom pieces we recommend 10mm thickness.

You can download the .DXF and the .F3D files, just modify/check these measurements.

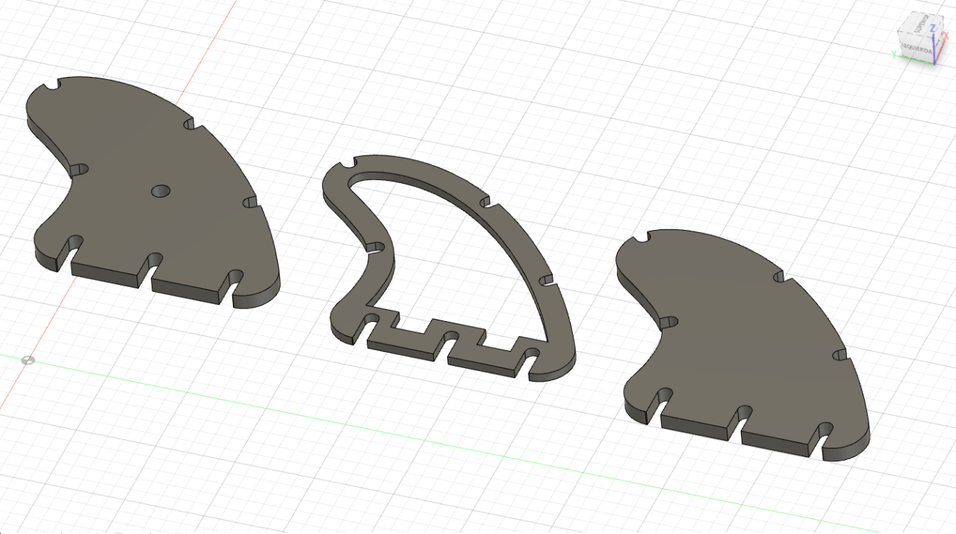

Once you have the correct sizes, then you will need to export each draw (3 in total) in .DXF file format. These files you will need to laser cut in stainless steel, we use a local laser cutting company, because these machines are industrial (the price shouldn't be too expensive).

Tell the company we need a M8 thread in the middle of the top piece. If they can not do it, you can also weld a M8 nut. This is for connecting the injection nozzle with the mould, check with your machine

2

Injection!

Once you have your laser cutted mould, it's time to fill it with plastic waste!

You will need seven M8x40 screws (or longer), in order to close the 3 mould layers.

As we commented, we use a M8 nut to connect the mould to the injection machine, you can play with different injection point positions. If you don't have a thread in your injection machine, you can just use the hole/injection point without thread.

We recommend to use recycled PP, as the PE tends to break easily.

3

Post-processing

As we are using a laser cutted mould, the edges are straight, so it is not hydrodynamic and could be a problem for surfing. We need to remove these straight edges, so we have to sand it, now the craft comes!

In order to keep the center line in the middle, and don't deform the verticality, just draw a line across the edge, and an offset perimeter in both faces, to don't remove too much material. We use a rotatory tool, use safety glasses and mask!

If we wanted to skip this step, we would need a CNC mould, more expensive than this one. But the object will inject with the hydrodynamic shape, without necessity of sanding.

4

Finishing

You can use a electric sand machine, it will help you to save a lot of time. Starting sanding with big grain to remove a big part (120), then we'll sand with medium grain (320), and for finishing small grain (800). The grain is just a reference, you can try with different grains, even you can polish (grain 3000 or more).

For finishing, We do a quick heat to improve the surface.