Making Fish Earrings using the Injection Machine

This is a step-by-step process of how the CITC Denełchin Fab Lab created fish-shaped earrings.productinjectionmould

More Information

1

Software, Hardware, and Materials Needed

Software:

To create the mold, we designed the 3D object file using Blender, which is a free, open-source CAD software.

We downloaded a rainbow trout 3D object file from Free3D, which shares free-to-use, user-created digital design files.

We uploaded the 3D object file into PreForm, which is the free software for the Formlabs 3D printer.

Hardware:

Formlabs 3D Resin Printer

Formlabs Cure L

Galomb Injection Molder

Materials:

Mold Release Spray (we used Alumilite brand)

Aluminum Master Mold Frame

Rigid 10K resin (for the 3D printer)

99% Isopropyl alcohol

#5 PP plastic

Tools:

Snippers and chisel

Drill and bit (we used 1/8 in.)

Earring hooks

Craft wire

Jewelry pliers

Wire cutters

2

Designing in Blender

A step-by-step description of the CAD design process is outside of the scope of this tutorial, but here is an overview of what we did.

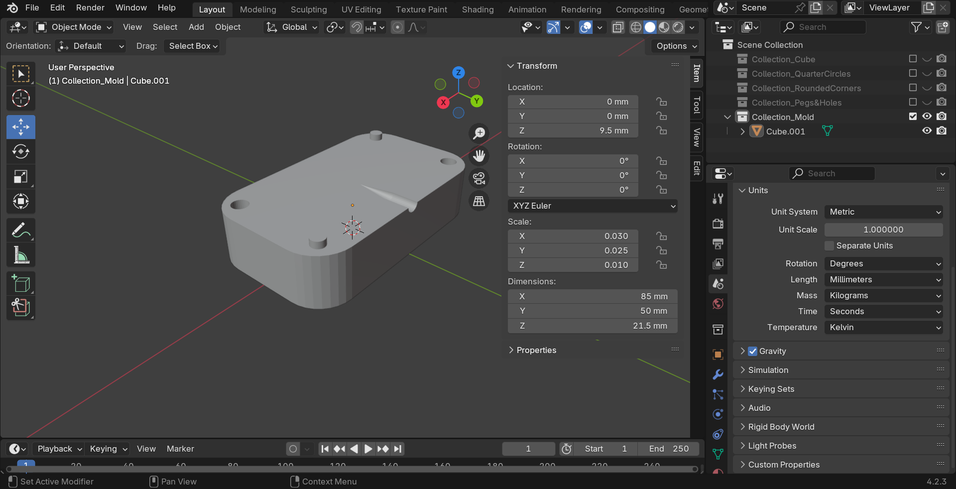

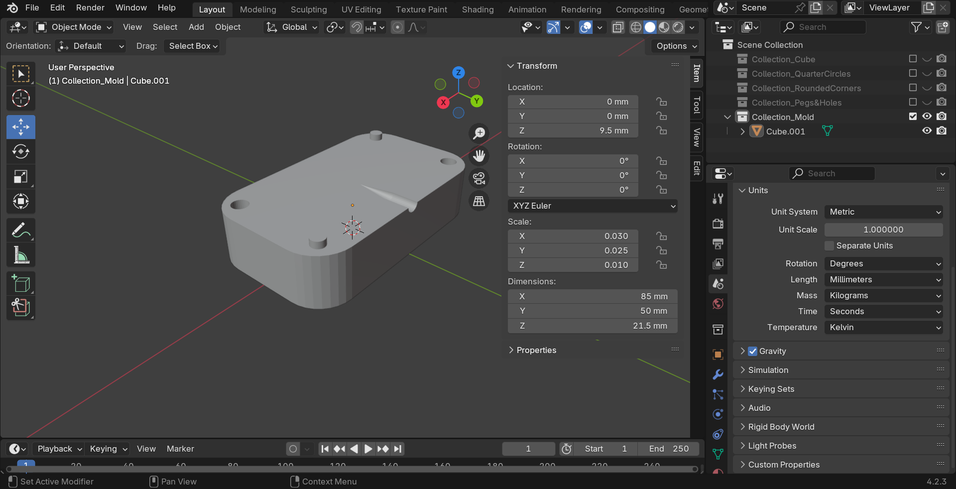

We designed a 3D object in Blender that would fit the MMB-401-1 Aluminum Master Mold Frame that is sold by the manufacturer, referencing the attached spec sheet. The dimensions of the object are 85mm x 10mm x 21.5mm - pictured is one half of the master mold. There are pegs so the two halves can fit together. Once we have the master mold designed, we can inscribe any shape that fits those dimensions.

We downloaded a 3D object from Free3D of a rainbow trout - thank you to user printables_models. The original object can be found here: https://free3d.com/3d-model/rainbow-trout-v1--202714.html.

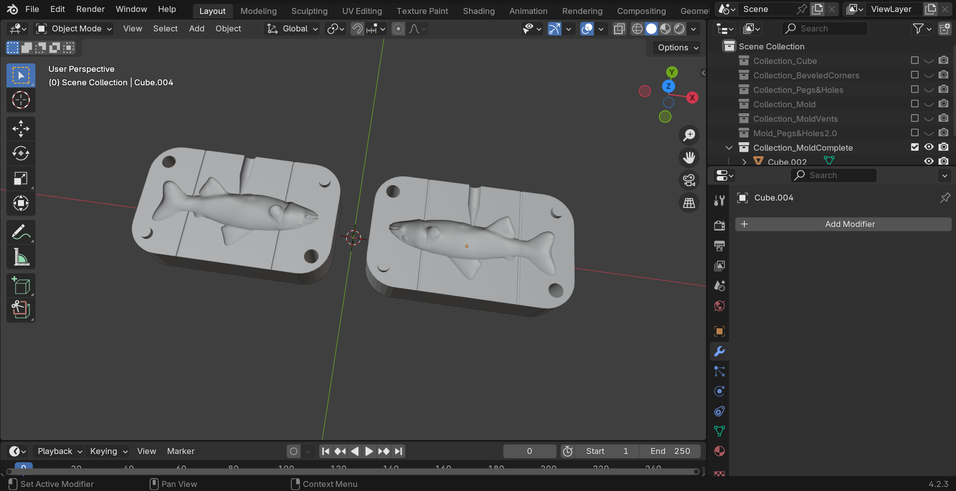

We sized the fish object so it would fit in the master mold, created a negative image using Blender's Boolean modifier tool, mirrored the image, and added air vents.

3

Printing with Formlabs

Now our fish mold is ready to be printed. The object file is uploaded into PreForm so it can be printed on the SLA resin 3D printer. We utilized the tools in PreForm to auto-orient and generate supports for the 3D-printed design. This design took about 8.5 hours to print. Once it was finished, we cut off the scaffolding. We soaked the mold in isopropyl alcohol for 30 minutes to dissolve the uncured resin. Then we put it in the Formlabs Cure machine for 30 minutes.

4

Using the Injector

Now that our fish mold is a reality, we are ready to use it in the injection molder. We insert the 3D printed mold into the aluminum master mold case and apply mold release spray. Be sure that the fin cavities are well-seasoned with the spray. We load the mold into the injector and set the temperate to 235°C. We've had the best results with #5 PP plastic, though we have experimented with different plastic types. If you do another type of plastic, be sure to set the temperature accordingly.

We fill the chamber with plastic flakes. Once it's melted, pull the lever!

To quickly cool the plastic fish for easy removal, we submerge the encased mold in water. While it is underwater, we pry apart the two halves of the mold extract the object.

5

Finishing Touches

We drill a hole in the tail fin for the earring hardware. We thread craft wire through the hole. With the wire, we wrap a loop for the earring hook with the jewelry pliers. Finally, we attach the earring hook.

Since we're making earrings, we then repeat the previous step so we have two fish. This design is also suitable for pendants and keychains if you want to make just one fish.