Jump rope handles mould

Jump rope is a nice tool for keeping fit. This mould allows making a jump rope handle. It is intended for the injection machine and is quite easy in operation. Depending on the injection machine arrangement, some modifications to the mould might be needed. Local price ±120 EURinjectionmould

More Information

1

Download

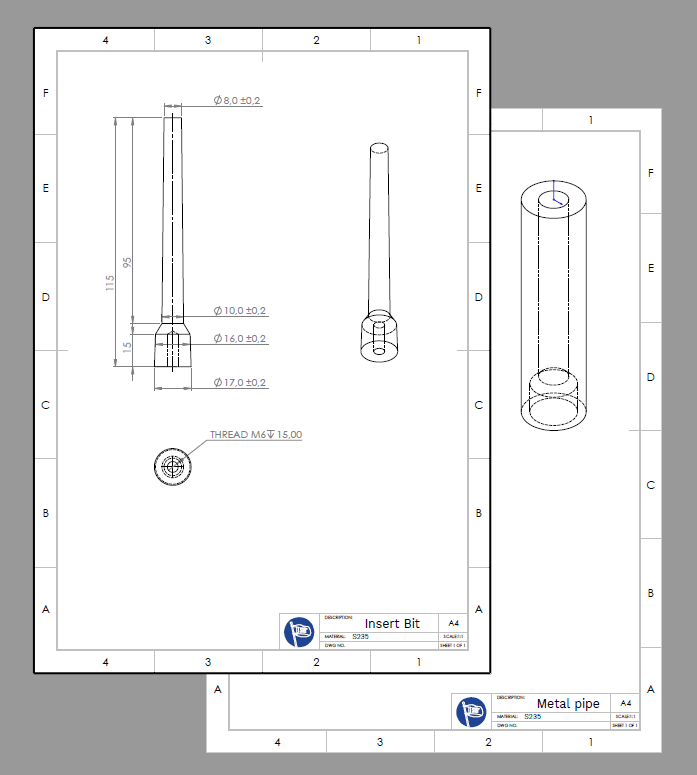

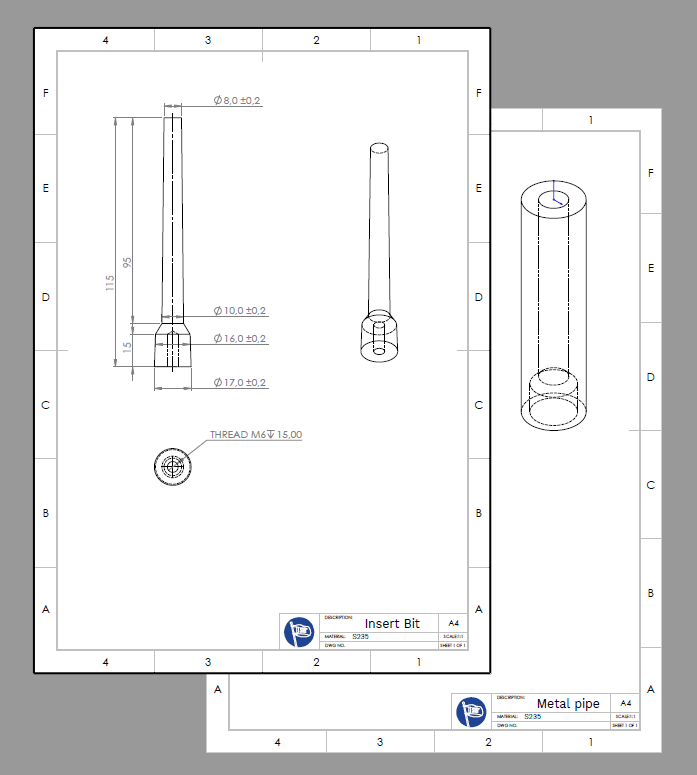

The design consists of 4 lasercut plates, a pipe and an insert. The files include all necessary formats to order the mould from a local fabrication.

2

Manufacture

The pipe and the insert require metal machining - lathe work. This were ordered from a local fabrication. Drawings included.

The plates are lasercut.

The thicker plates hold the pipe and insert. One of the thicker plates attaches the insert with a bolt.

3

Inject the handles

The injection moulding process starts with preparation of the machine, the material and the mould.

Material suitability:

PP [5] - fills the mould nicely and with no problems.

HDPE [2] - more viscous and requires higher injection pressure. From our experience very challenging to work with this mould.

The mould needs to have a proper adapter/connection method. We use a car jack to push the mould inlet onto the injection nozzle.

Some lubrication is needed on the insert bit. If the product is left to cool for too long on the insert, it tends to shrink and get stuck on the insert. The best way to release is to use rubberized gloves and pull in the twisty/rotating manner.

Follow-up: the injection point needs to be clipped off with pliers/ knife and a hole should be drilled at the end with a drill bit 6-8mm in diameter. It is easier to drill from the inside of the jump rope handle with a longer drill bit.

To finish the jump rope, we use 6mm rPET paracord type rope (recycled).