Injection Machine Quick Connect Upgrade

This How-To will show you how to upgrade your injection machine and molds to make your injection process faster, safer, and more efficient! This trick works on any injection mold that have a threaded connection to the machine nozzle. Install a brass garden hose connector and voilà!injectionhackmould

More Information

1

The problems with injection

The injection machine is a great tool to raise awareness about plastic pollution and demonstrate the plastic recycling process.

However if you need to produce many parts, the process can be a little tedious and wasteful:

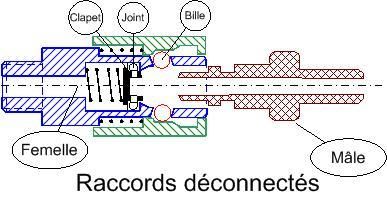

-Threaded Connection ---> Often get clogged up by molten plastic, making the assembly difficult and require cleaning between each cycle

-Hard to demold ---> Mold connector creates undercut shapes and is hard to demold

Here are the specifications that the upgrade system must achieve:

1- Allow molds to be attached and detached from the machine in 1 movement

2- Reduce uncomfortable position for the operator

3- Reduce production waste

4- Be usable with gloves easily

5- Reduce cycle time

6- Revoke the need for a plug

7- Do not require cleaning between each cycle

The trick is to use a brass garden hose connector, available in gardening and home improvement store, to easily connect your mold ans be more efficient!

2

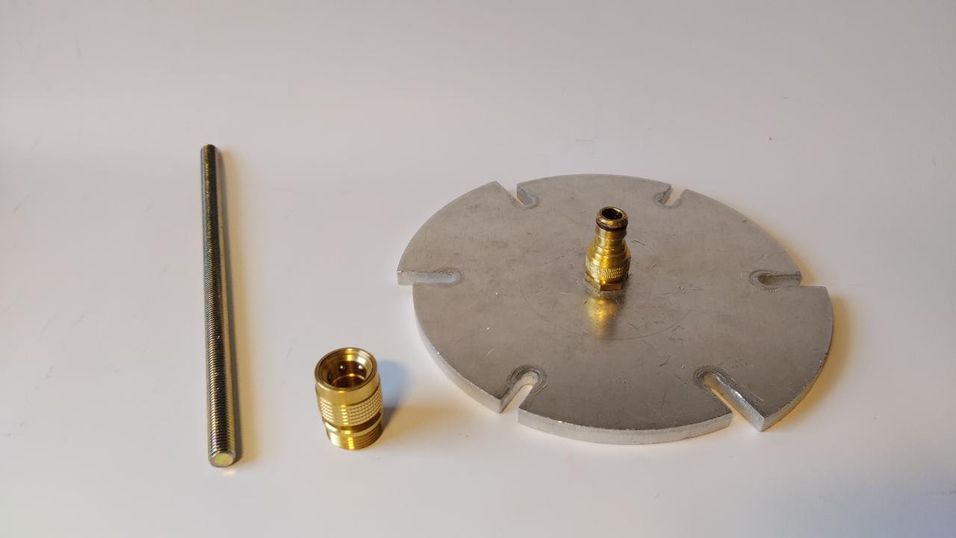

Bill of materials:

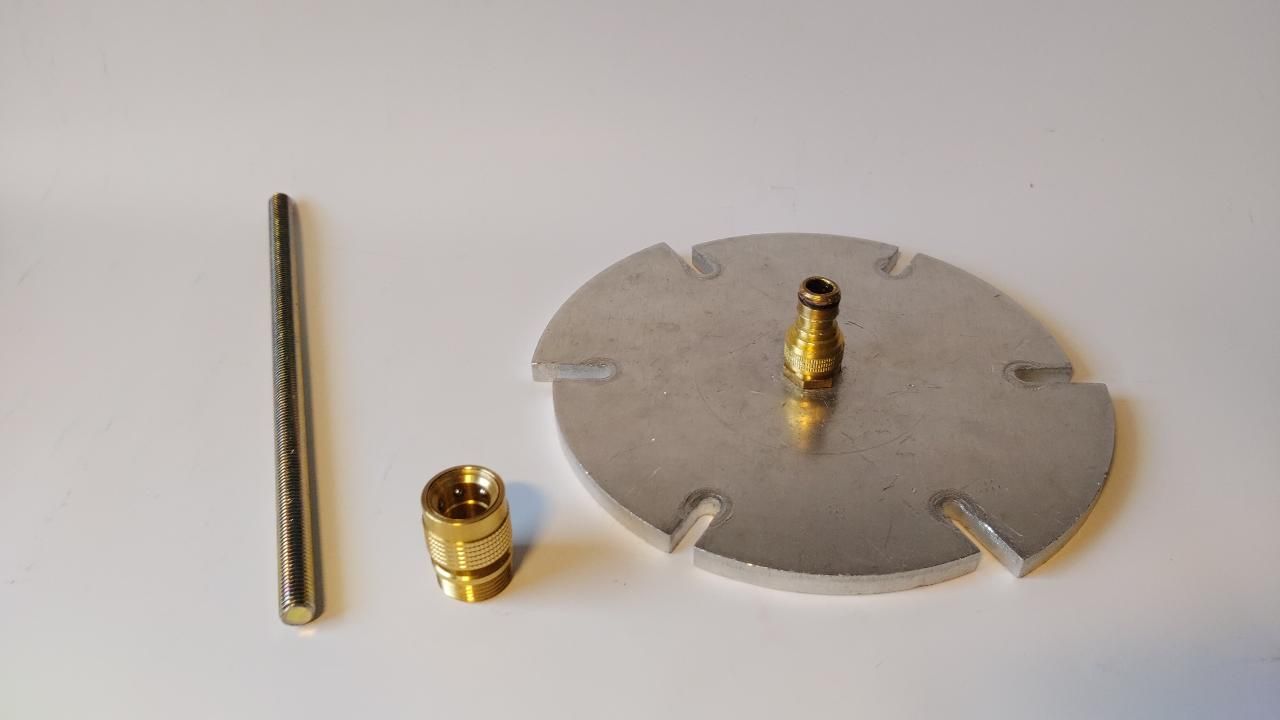

You'll need :

1 - ¾ inch female brass garden hose connector with threads

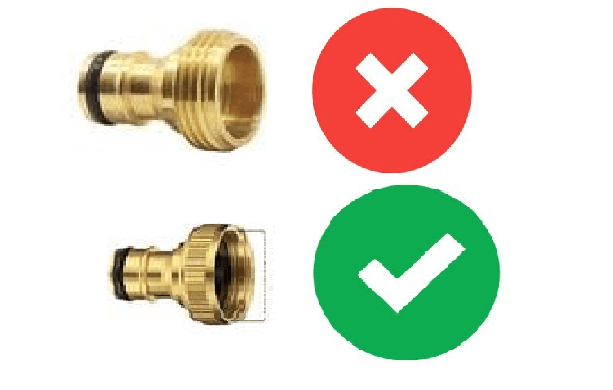

2 - ½ inch male brass garden hose connector (or any other size depending on what fits on your mold), with INSIDE threads

1- ½ inch brass endcap

1 - 1 cm long piece of M14 threaded rod (or a 14mm diameter round)

1- 10mm drill bit

ATTENTION: Buy the right hardware! See pictures

3

Assembly

For this step you will need a drill and a vise or even better a drill press .

1- Drill a 10 mm hole trough the piece of M14 threaded rod

2- Place this part inside your mold ½ connector, it should fit inside and fill the space.

3- Screw the male connector on top of it

4- Drill with the 10 mm drill trough all the parts to enlarge the hole diameter.

5- Take the second male connector and screw it to the endcap --> Here's your new plug :) .

4

No more undercut!

The piece of rod is here to fill the space inside the ½ inch connector. The molten plastic then flows trough the 10 mm round channel, and the sprue can be pulled out from the mold easely!

If you forget the spacer