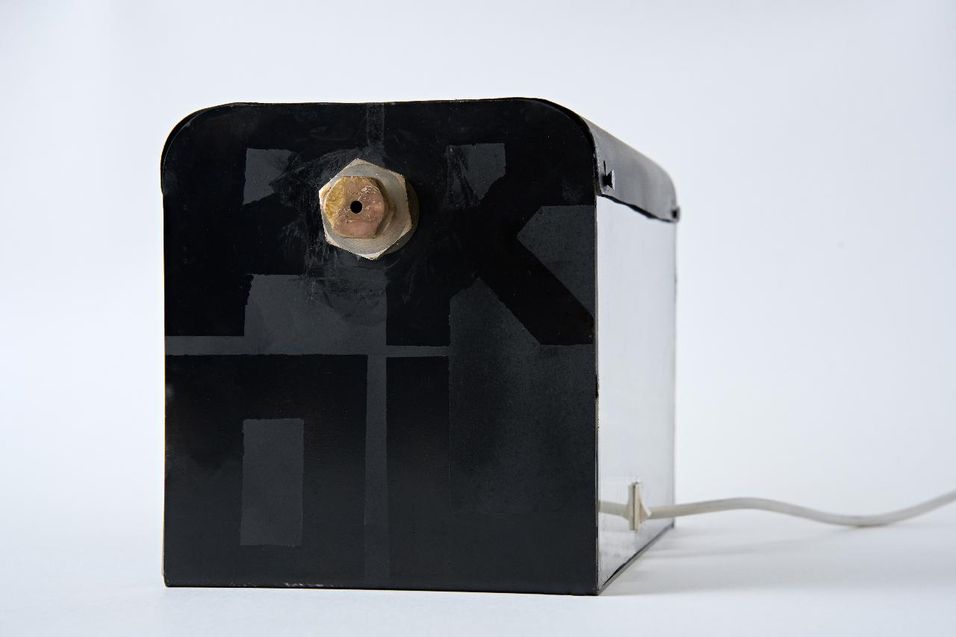

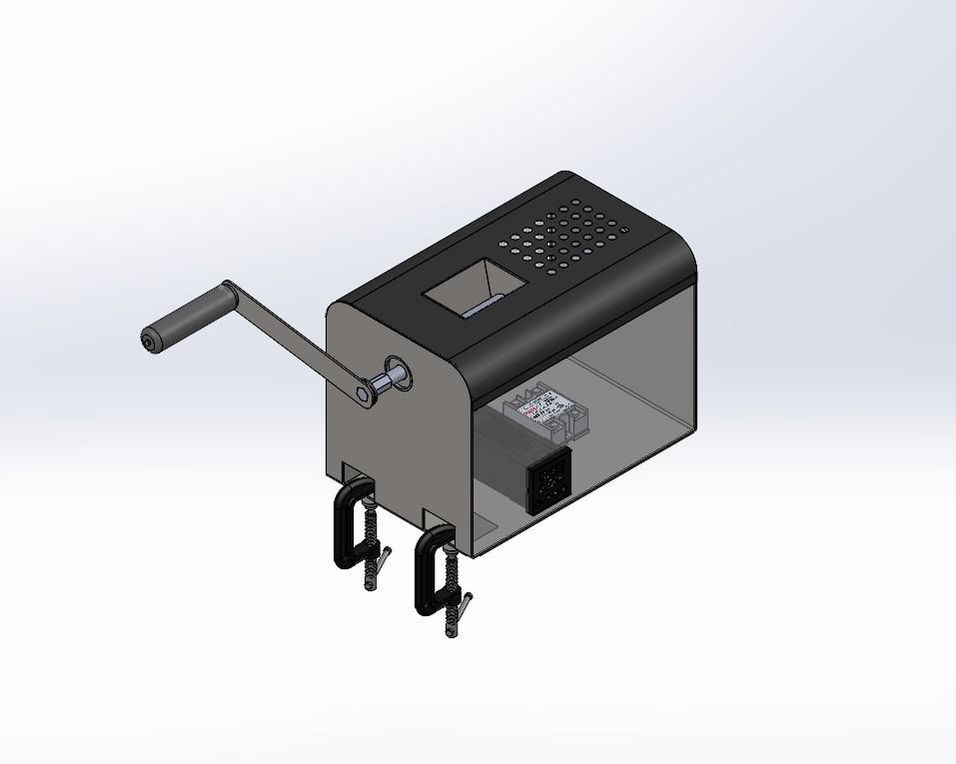

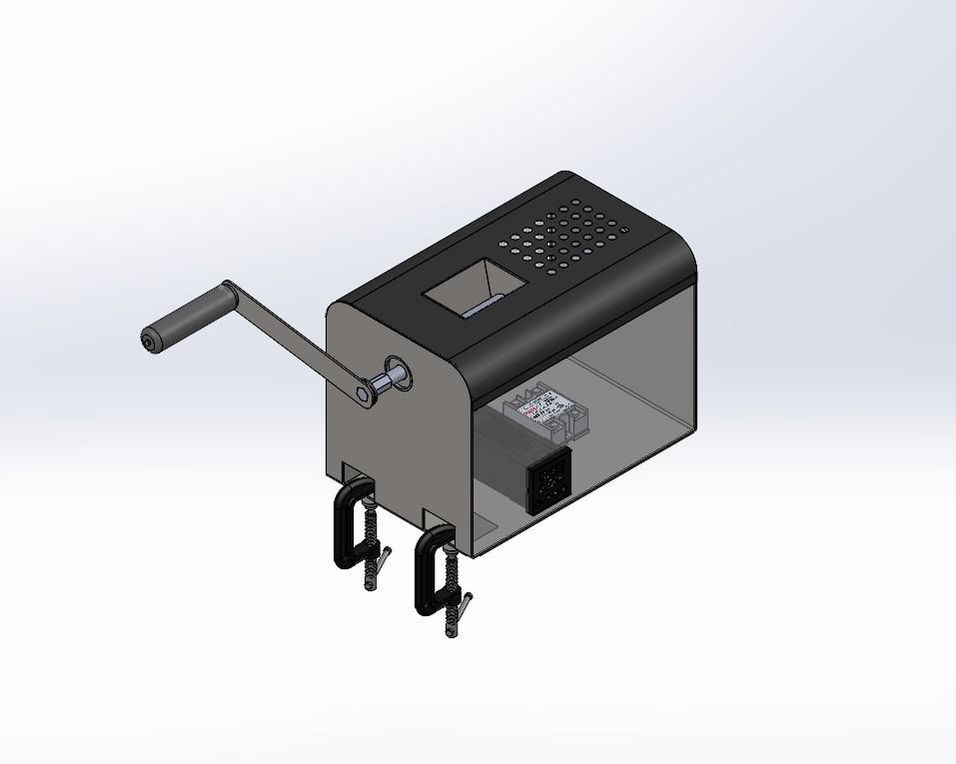

Desktop hand table extruder

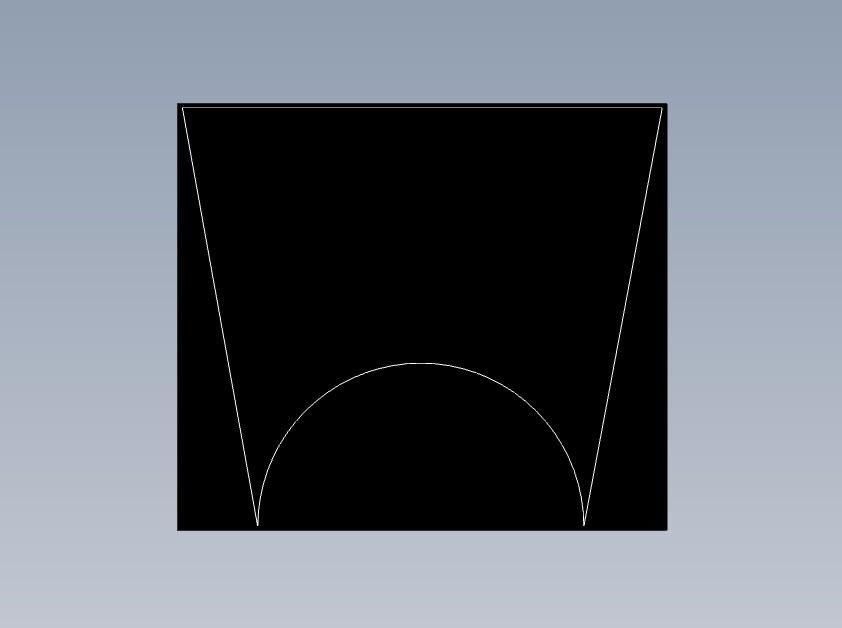

Desktop extruder for home use. It has a socket for fastening with clamps to the table. Transparent case walls allow you to see the components. Has a surface for pre-drying plastic. In this folder you will find: 1) 3D CAD (.SLDPRT) 2) Photo set assembling extruder. This extruder is designed for small batch production as well as public presentations. This is completely my development, but feel free to make changes to it at your discretion. Fill in the plastic, twist the handle and "voila!" new eco-friendly recycled product! Suitable for working with plastic at melting temperatures up to 300 degrees. I built it for 220 volts (you can adapt it for yourself).other machineextrusionmelting

More Information

1

Order electronics for a project

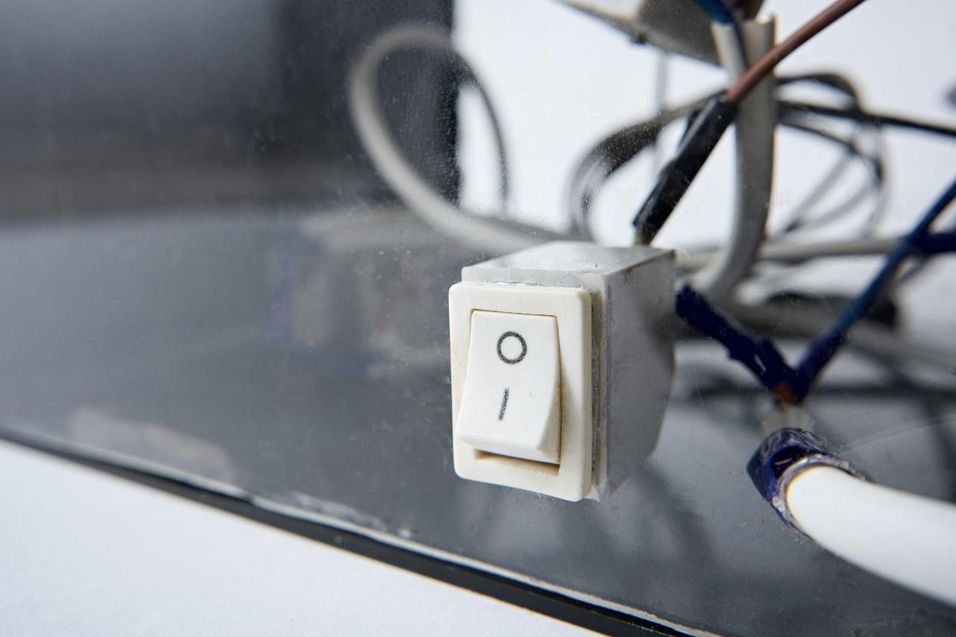

It will most likely take time to ship, so it's best to start there. REX-100 and solid state relay with thermocouple can often be found as a kit. For heating, I used 2 ring heaters. Also, add a switch at the back.

2

Decide on the materials

Various materials were used for the project:

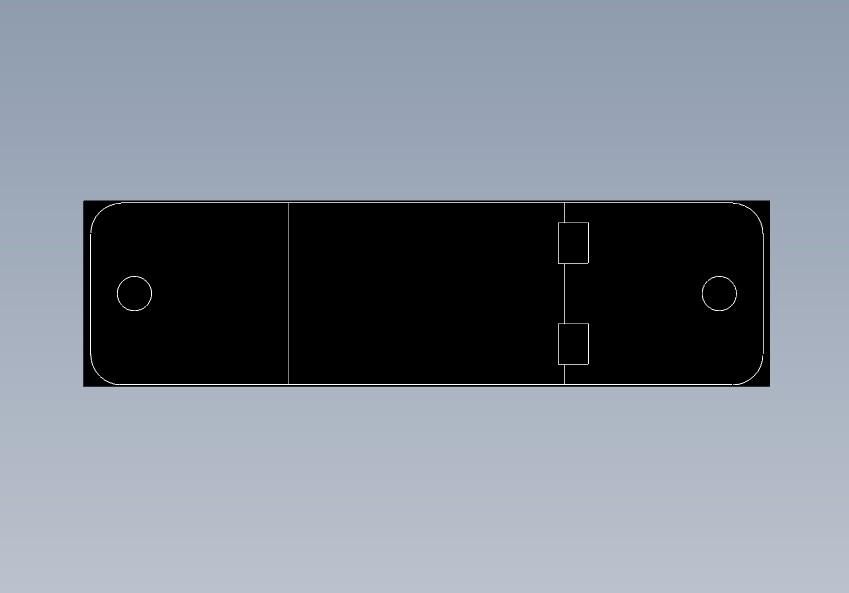

for the base of the mechanism, the base and small parts - structural steel 2 mm;

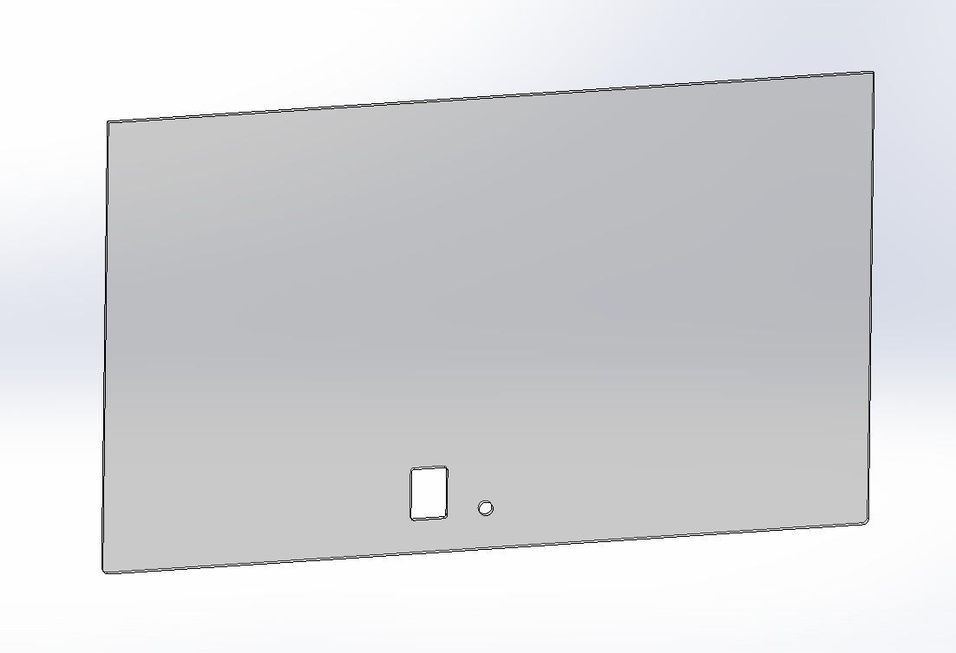

for walls - plexiglass 2 mm;

for handles - wood or plastic;

for the roof - sheet steel 0.4 mm.

3

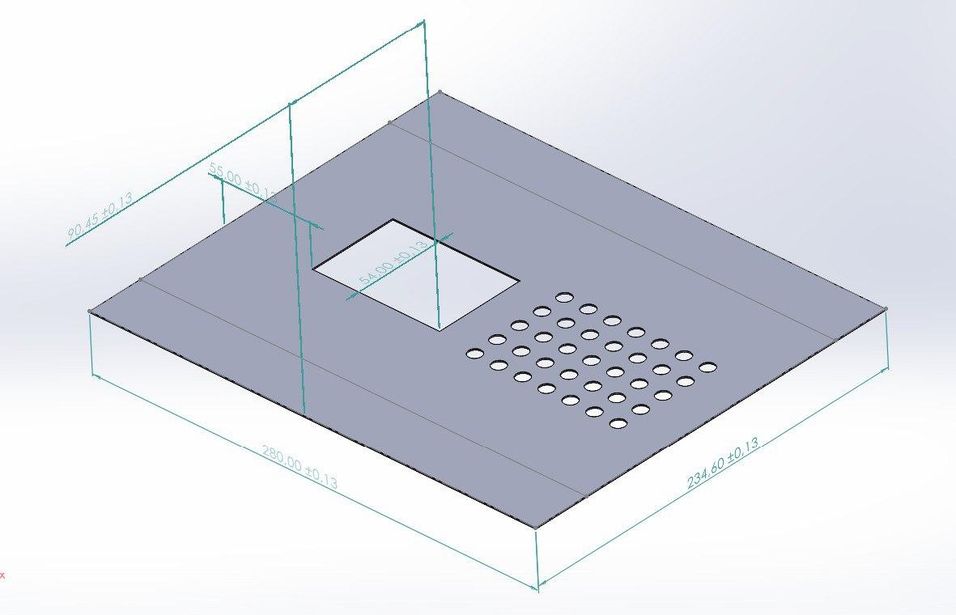

Save files for laser cutting

Check with the local manufacturer in what format they need to transfer files for laser cutting and bending and convert the files to this format. Usually in the format .dxf, .cdr or .dwg

Thin sheet steel for the roof can be cut and bent by hand. I recommend cutting the rest exactly according to the dimensions of the drawing automatically. This will save you time and give excellent quality at a reasonable price.

4

Order cutting of materials

You may not have to buy cutting materials yourself, they will already be in the plexiglass steel cutting service. This is beneficial, you will not be left with pieces of unused material.

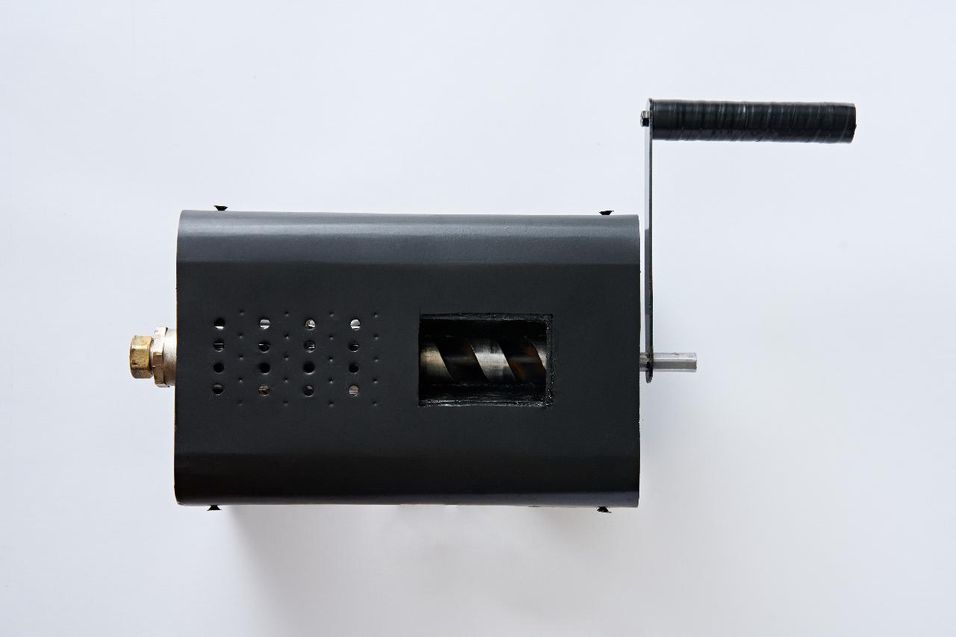

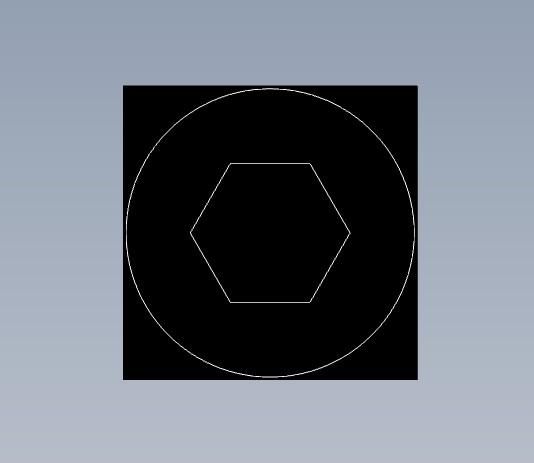

With a heated pipe, it's a little more complicated. You can thread a regular pipe or weld a pre-threaded flange to a pipe. I chose the second option. It requires welding and post-processing, but if you do not have the necessary tools, this is not a bad option.

Also, it will be necessary to make a cut in the pipe for the funnel. Its walls will be cut with a laser, they will remain to be welded.

Instead of a professional auger, I used a large 28x350 mm wood twist drill.

Used paint to prevent corrosion. Also, wires will be needed to connect the electronics. Detailed instructions for connecting the kit used are available online.

Clamps are required to attach to the table.

5

Add the design you like

I wanted this machine to be beautiful. Add design elements to your liking to make the device a pleasure to work with. And… done!