Create a shut off for the beam mould

Making a shut off for the beam mould to prevent plastic flowing out after disconnecting from the extrusion machine.extrusionmould

More Information

1

The problem of plastic flowing out of the mould

When working with the extrusion machine and fine tuning the process we wanted to address the outflow of plastic when the mould has filled and you unscrew it from the nozzle of the extrusion machine. We have a cooling gutter close by so the mould goes within a second or 2 in the water. Still the overpressure in the mould makes the molten plastic flow out quickly.

Its extra waste and it takes time and effort to remove it. We came up with this:

2

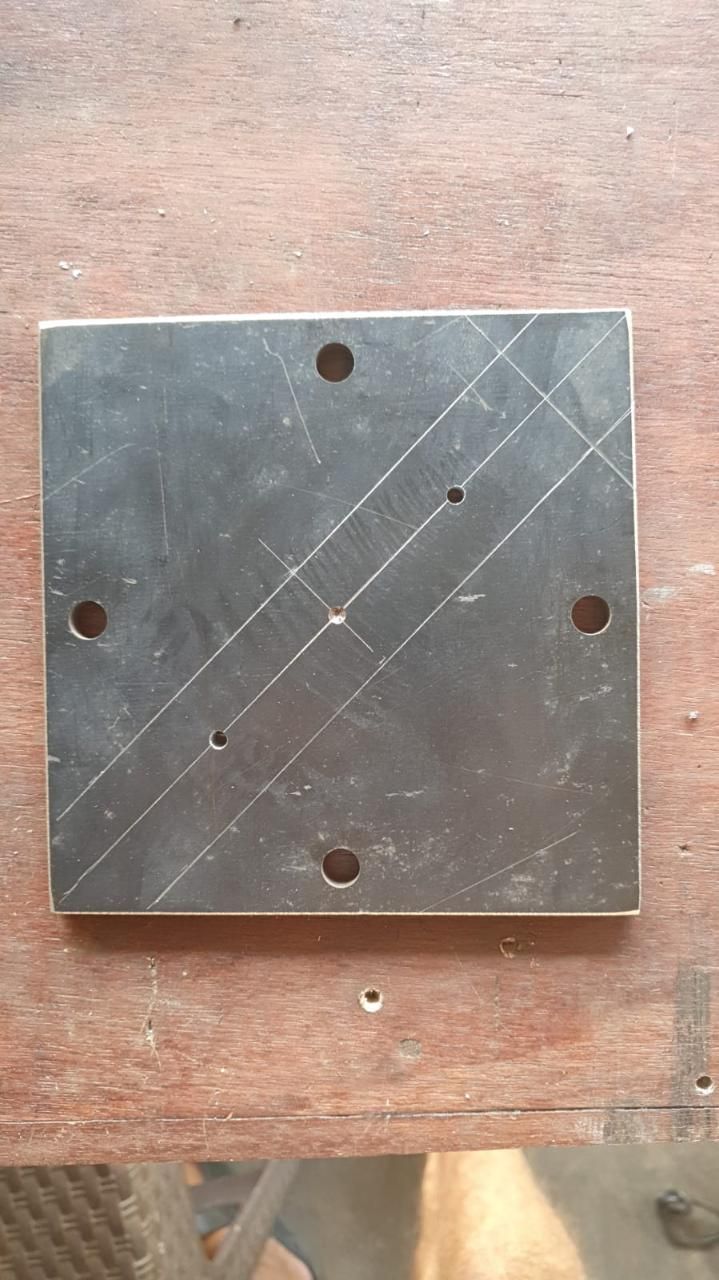

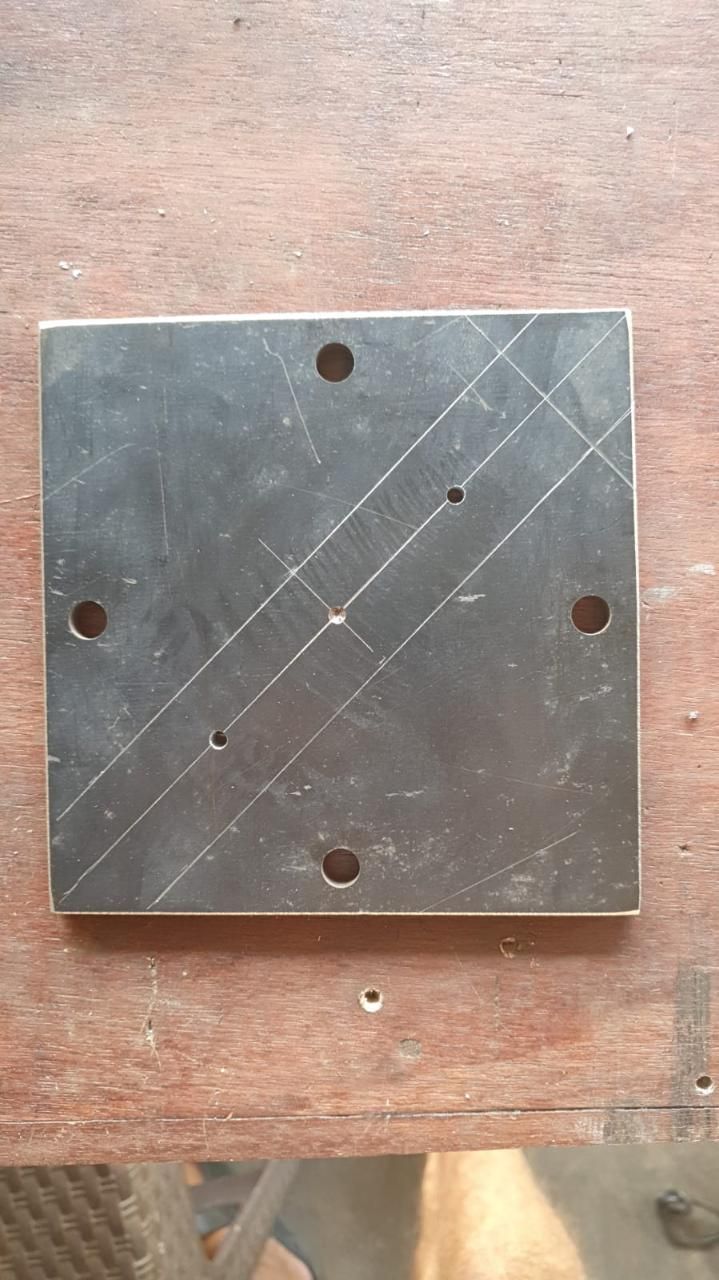

Make a third plate

To be able to close of the beam mould from the extrusion machine while still connected to it, make use of an extra steel plate. This plate has the same dimensions and hole pattern as the 2 other plates.

Depending of your hole pattern, think of the best way to create a strip that, if cut out, can slide over the injection hole. We made an arrow shape to create a fixed stopping point.

3

Make a smart hole pattern

After you cut out the slide strip you can attach the 2 symmetrical parts to your nozzle plate and tag weld them to it (see pic 1). Give the arrow slide a center hole thats inline with the nozzle plate hole. This is your reference point. For us it worked best to go 4cm each way of the center point to create two holes. One 4mm close to the arrow head and the other 20mm on the other side. When the arrow slide is in its open position the 20mm and the nozzle hole are inline (See pic 3). In this position you can drill the 4mm hole all the way trough the nozzle plate. Use any kind of pin to secure the arrow slide in place so the big holes are aligned.

4

Ready to rumble!

Now its time to put everything together. One extra 4mm hole needs to be drilled trough your beam mould plate. This way the security pin goes trough all 3 plates when in the open position. Time to start extruding! We have the end of the mould welded shut with only a 5mm pressure releave hole. This is also the indicator when the mould has filled. We let the extruder run a little bit after that to put some pressure on the beam. After stopping the extrusion machine, pull the pin and tap the arrow slide shut with a hammer. Now you can unscrew the mould relaxed and gently let in cool in whatever way work best for you.

After cooling down, remove the nozzle plate. The beam should slide out or its needs a few taps at the back!

Minimal waste and ready fast for the next beam.