Affordable Cat Housing

Updated 1yUpdated over 1 year ago

How to draw custom shapes and designs by hand and then cut in CNC. HDPE

More Information

1

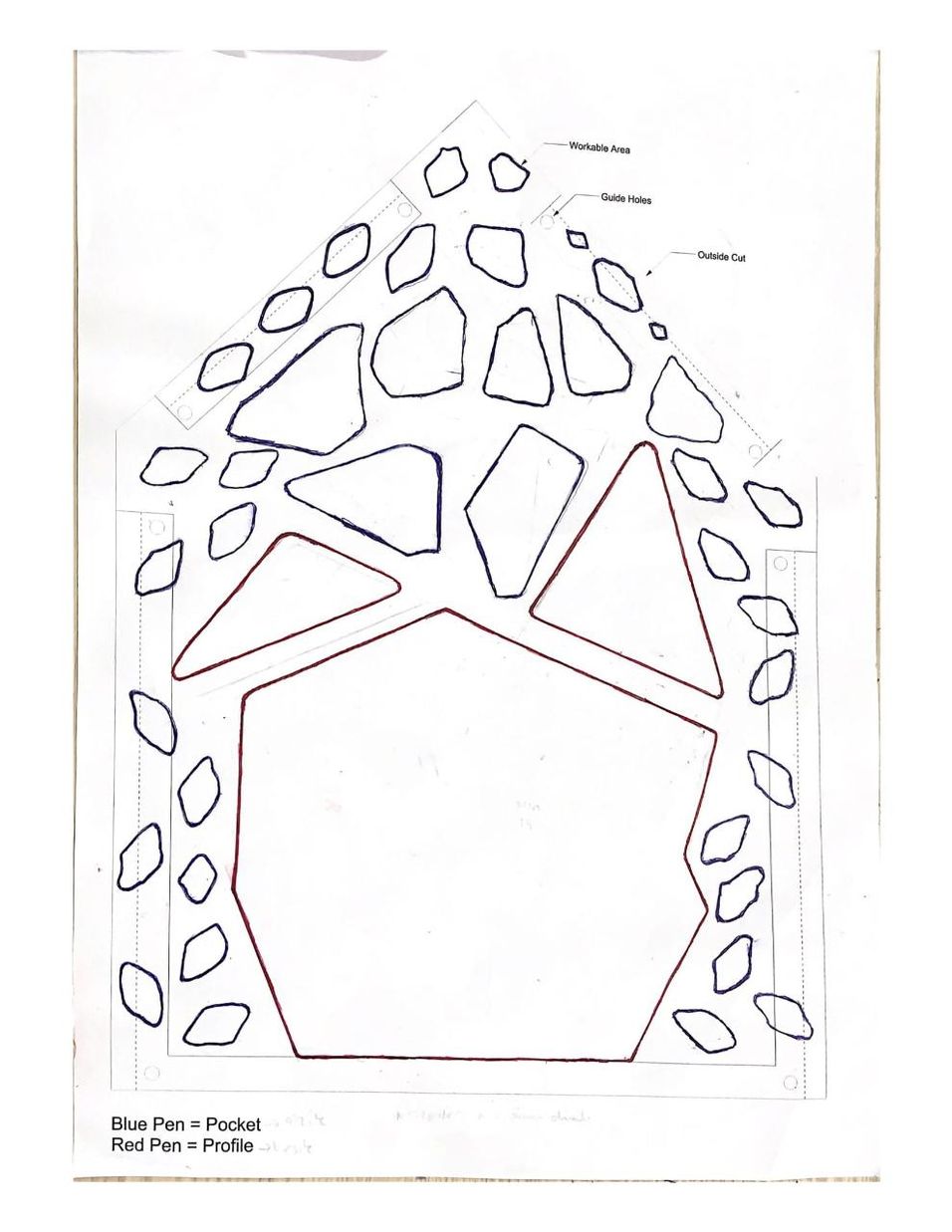

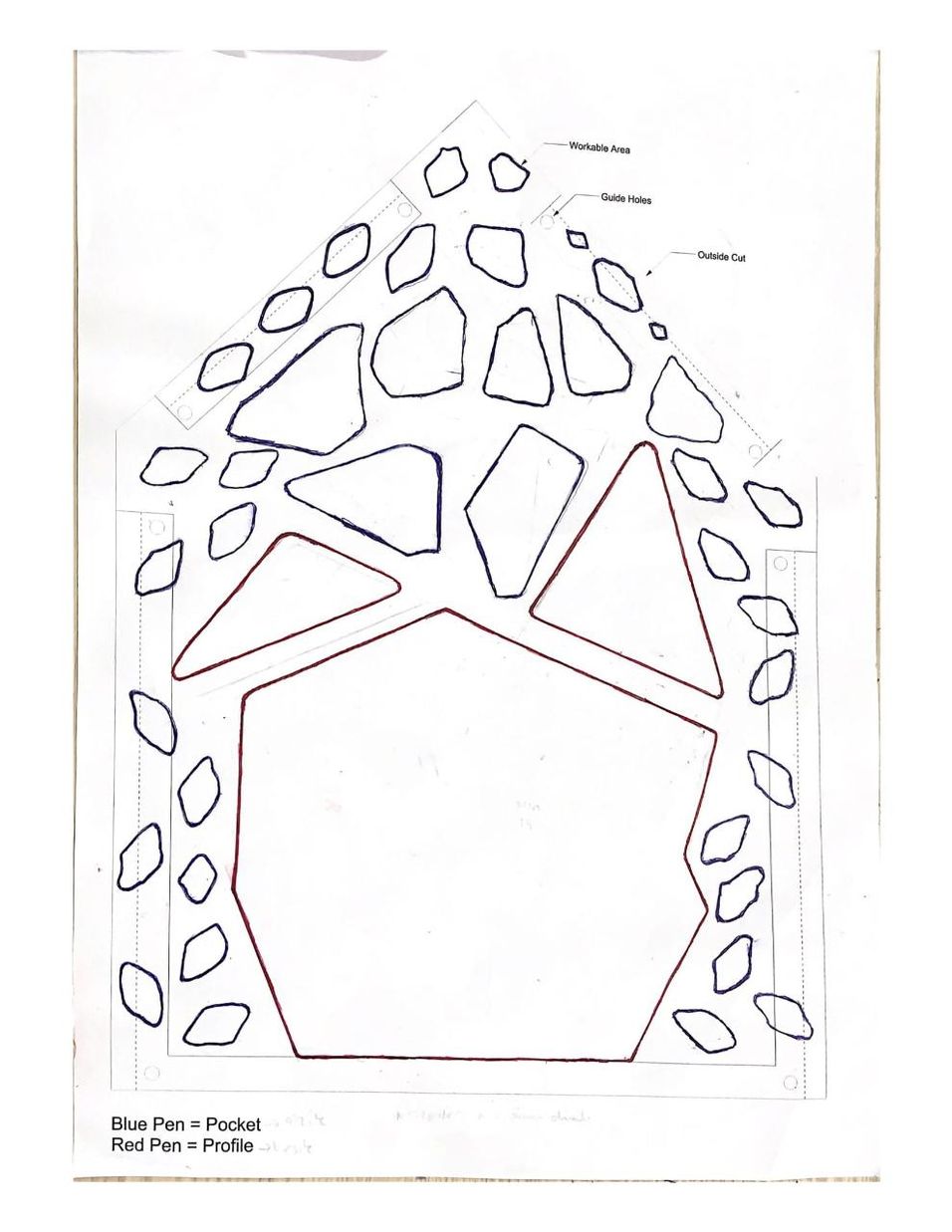

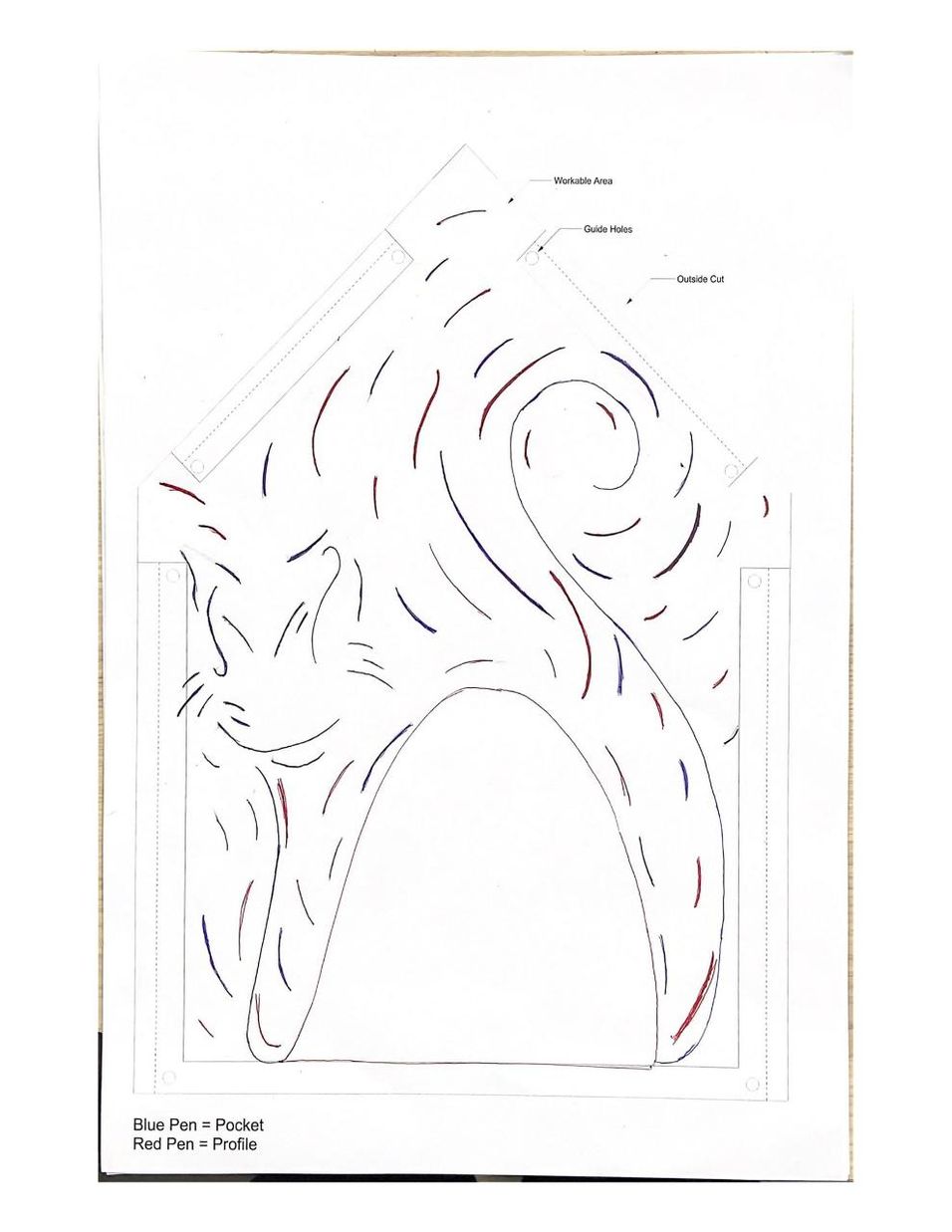

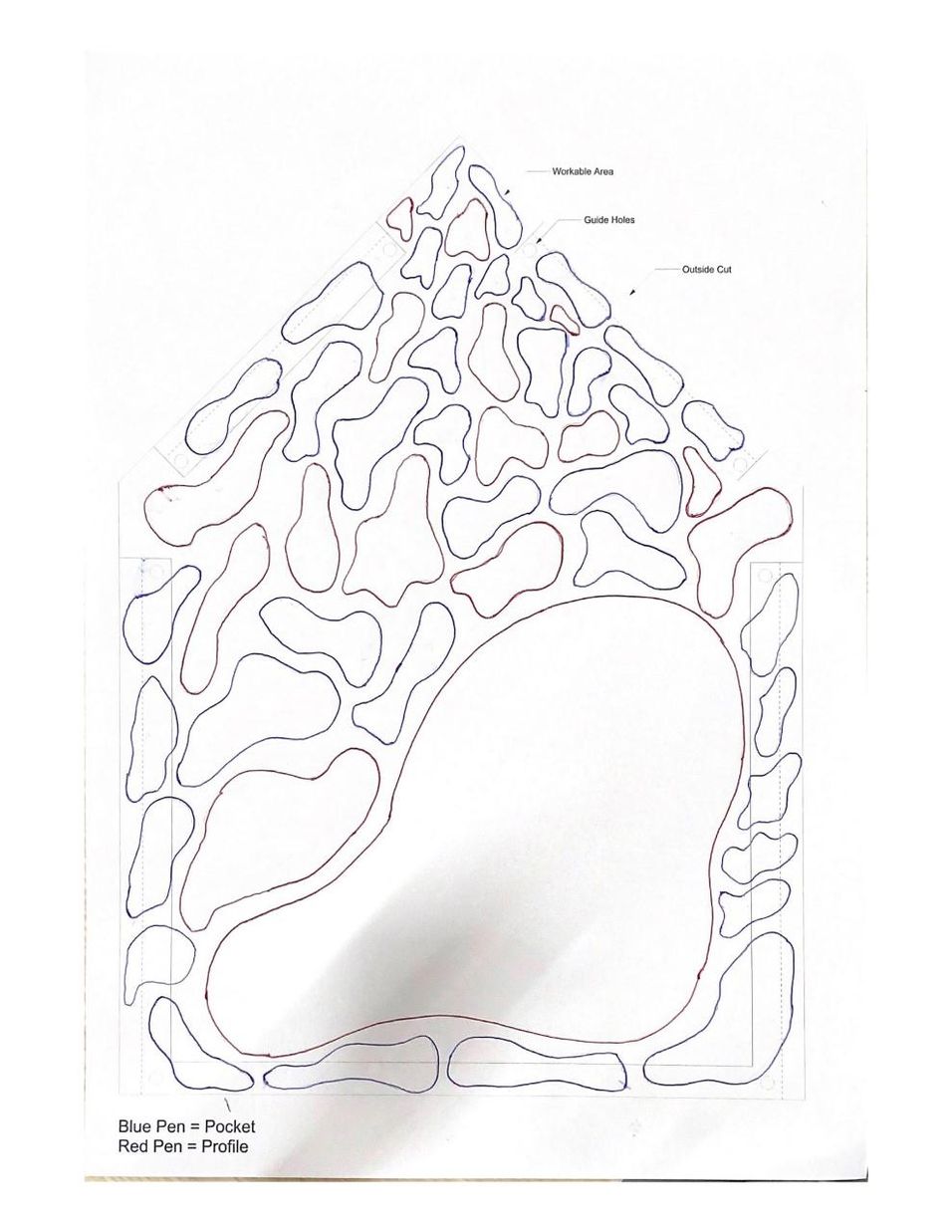

Draw you design in 1:1 scale

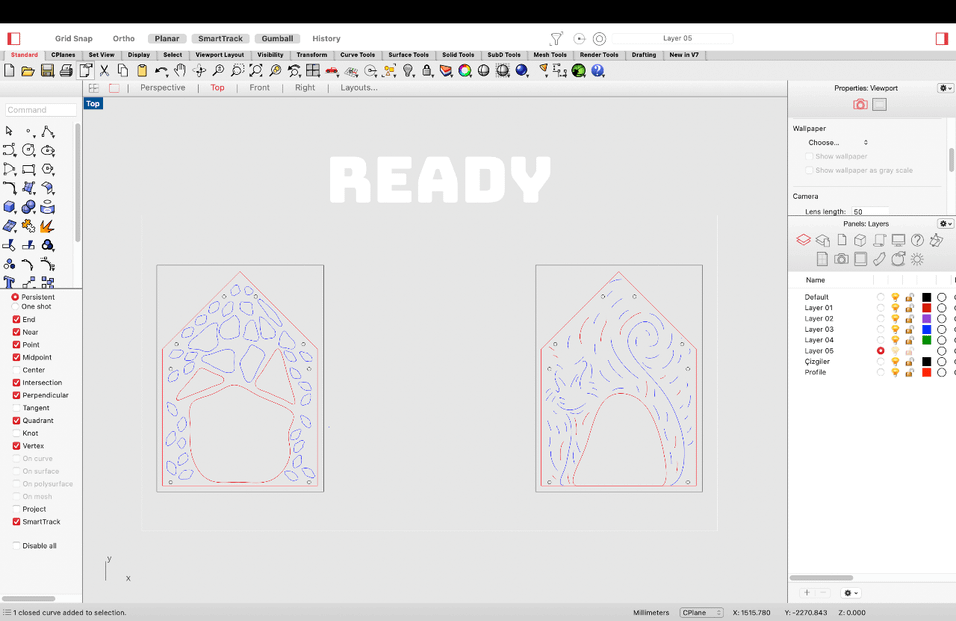

For this first step, we provided 1:1 scale documents to draw on. Participants then drew their designs. The blue lines are for pocketing (not cutting the material through) and the red lines are for profiling(cutting the material through).

2

Scanning drawings

In this step, we scanned(took pictures and used a scan filter like CamScanner) the drawings. The important part is to have a high-contrast image. Something like a photocopy.

3

Converting drawings into CAD

We used the Rhinoceros 3D application and the Vectorize plugin to import the drawings as lines in Rhino. We then cleaned the lines and simplified all the curves using the rebuild command. This ensured smoother curves with fewer control points. Again the blue lines are for pocketing (not cutting the material through) and the red lines are for profiling(cutting the material through).

4

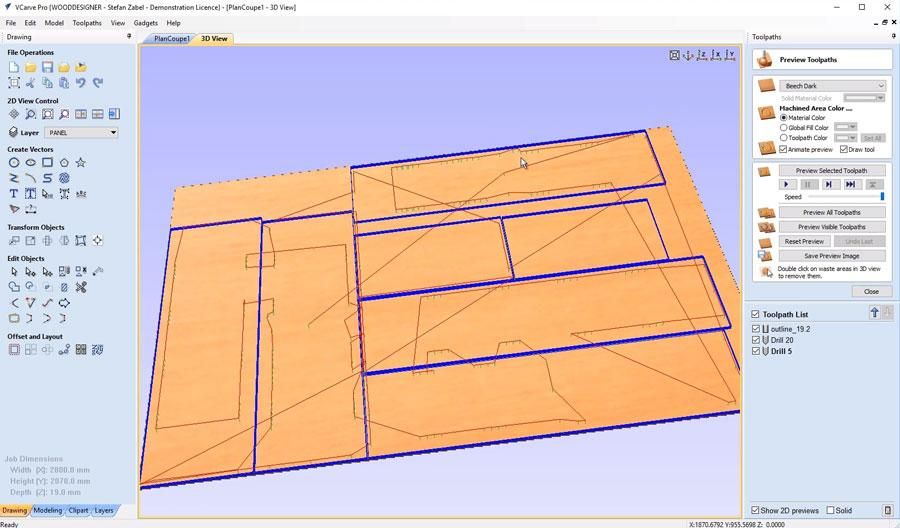

Preparing for CNC

For this step, we used the VCarve application. We entered the width, length, and thickness of our material. Then we selected the blue lines and chose 'pocketing' and for the red lines we chose 'profiling'. Every machine is different so this step will be different for everyone.

5

CNC miling

This step involves cutting the material according to the designs. For this, we screw four corners of our sheet material to the CNC bed and specify to the CNC machine where are the x, y, and z locations of the corner of the sheet plastic. An important thing to remember is to double-check the cutting pattern from an elevated point (meaning the Z coordinates should be higher than the material) to make sure that the CNC bit is not hitting any of the screws and that the design fits in the sheet nicely and is not offsetted to one side.

6

Assembly

The last step is to assemble all sides of the Affordable Cat Housing using screws. We used two materials; our plastic sheets and OSB panels.